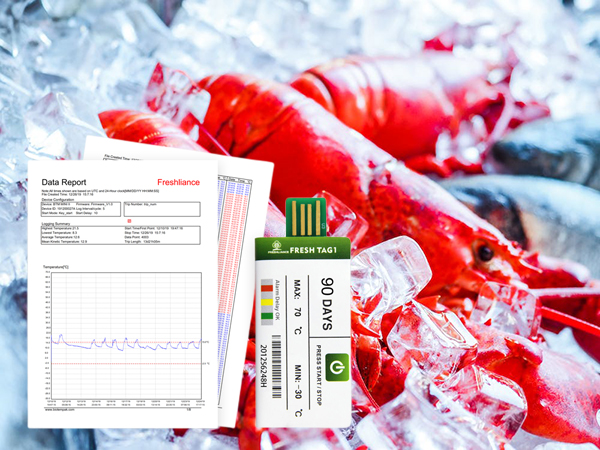

Freshliance Fresh Tag 1 single use USB temperature data logger is the ideal choice for monitoring temperature at the lobster cold chain, ensuring their best flavor when they arrive at your table.

Autumn is the prime season for catching lobsters in the cold waters, and the lobsters will soon find their way into many winter feasts, from office holiday parties to Christmas dinners and New Year’s Eve celebrations. Lobster transportation relies on cold chain logistics. The key to keeping lobsters alive during shipping is to make sure they are under a certain temperature and moist at all times.

While lobsters have gills, they can survive out of the ocean for up to four or five days if kept cool and moist. Keep the lobsters in a cold location at 45 to 50 degrees Fahrenheit for several days before traveling or shipping. When kept cold, they require less oxygen to survive the trip. To keep lobsters alive during shipping, start with keeping them at temperatures no more than 40°-50°F. Optimal shipping temperatures are between 32° and 40°F. Be careful not to get the lobsters too cold - they freeze at the same temperature as seawater: approximately 29°F. Meanwhile, keep the container as close to 100% humidity as possible.

Keeping the nonbreaking cold chain logistics is the key to making lobsters alive and fresh. Our Freshliance Fresh Tag 1 single use USB temperature data logger is specially designed for cold chain logistics. This USB temperature sensor can be used for lobster cold chain temperature monitoring. Freshliance single use USB temperature data logger comes with a compact design to save space during transportation. You can place these temperature data loggers with your lobster cargo in ships and trucks. Moreover, this data logger USB enjoys an IP67 high protection grade. A humid and moist environment cannot disturb the logger recording. Most importantly, this USB temperature sensor is equipped with red, green and yellow indicators, which can indicate its alarm, ok and fault status. After the trip the completed, you can tear off its plastic bag, and plug it into the computer. The report with graph and table will be automatically generated. This report will be the necessary evidence for the product owner and the cold chain carrier if the cold chain performance objection is required.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文