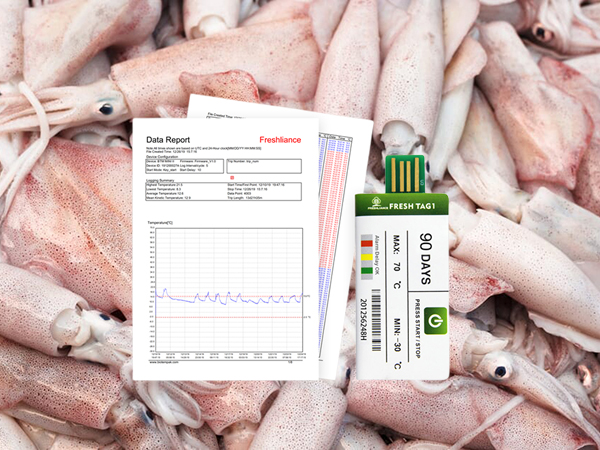

Continuous Fresh Tag 1 single use usb temperature monitor can be used to provide evidence that the cold chain has not been broken during transportation.

Squids - the nutritious and high-calorie gift of the sea. Their meat is rich in minerals and vitamins necessary for the body. Squid or calamari is also known as a cephalopod mollusk and belongs to the same family as the octopus and the cuttlefish. It is an extremely popular type of seafood used a lot in Mediterranean and Asian cuisines and is an ingredient in Spanish paella and fish stew. Global seafood consumption has risen continuously over the last fifty years, and seafood is a highly traded food over the entire globe through complex distribution channels.

Seafood begins to deteriorate as soon as it is caught and killed, this is irreversible during storage. We can’t stop product from deteriorating, but we can control the rate that product deteriorates. To maximise the quality and shelf life of your squid, frozen squid must always be at a temperature of below -18°C. The required travel temperature should be maintained at all times because it is only in this way that the activity of microorganisms comes to a standstill and enzymatic degradation processes are largely suppressed. The temperature of squid in a supply-chain often fluctuates, which results in rapid loss of freshness, increased bacterial growth, and shorter shelf life.

Temperature measurements must be performed and recorded at regular intervals. Continuous Fresh Tag 1 single use usb temperature monitors can be used to provide evidence that the cold chain has not been broken during transportation. You can place these temperature data loggers with your squid cargo in ships and trucks. Moreover, this temperature recorder enjoys an IP67 high protection grade. A humid and moist environment cannot disturb the logger recording. Most importantly, this USB temperature sensor is equipped with red, green and yellow indicators, which can indicate its alarm, ok and fault status. After the trip the completed, you can tear off its plastic bag, and plug it into the computer. The report with graph and table will be automatically generated. This report will be the necessary evidence for the product owner and the cold chain carrier if the cold chain performance objection is required. It is also proof of the cold chain process complying with HACCP and ISO.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文