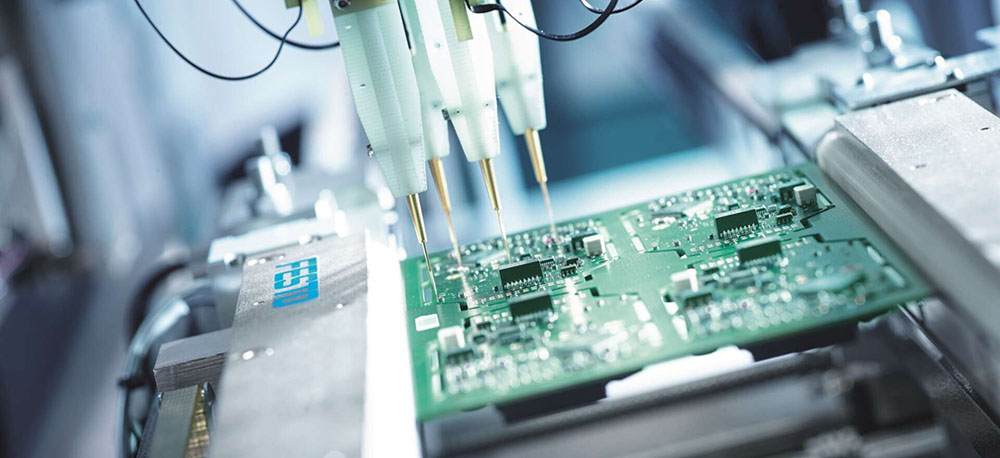

The printed circuit board is an insulated board on which wire is laid to create a circuit. They are a critical and very necessary part of all electronic products. They are in everything from complex computers to basic smartphones. It imposes strict regulations on the temperature and humidity of the environment during the manufacturing, assembling, and production process.

The printed circuit board assembly workshop clean room temperature and humidity standards are temperature 23 ± 3℃ and humidity 30% to 70%.

This is mainly for the solder paste to work in a better environment, the temperature will affect the activity of the solder paste, and have a specific influence on the activity of the solvent associated with the flux added therein.

High temperatures increase their activity and ultimately affect the effect of screen printing and reflow. It is prone to the phenomenon of solder joints and solder joints.

The magnitude of the humidity causes the amount of moisture that the solder paste inhales in the air. If too much water is inhaled, it will cause air voids, flying, and welding. Therefore, balancing within the above standard can ensure the normal operation of the process.

Our BlueTag TH20 Bluetooth temperature and humidity data logger can be used for PCB assembly workshop environment monitoring.

BlueTag TH20 is a smart Bluetooth wireless temperature and humidity sensor based on Bluetooth communication technology. This bluetooth temperature data logger features a wide measurement range from -30℃ to +70℃, and from 0 to 100%RH, and high accuracy of ±0.3℃ and ±3.0%RH. It can precisely capture subtle temperature and humidity changes in the PCB assembly workshop environment.

You can attach Bluetooth temperature and humidity data logger to the PCB assembly workshop wall. Before using it, you can configure parameters on our Android APP T-keeper, which can be found in Google Play. Scan the OR code on the back of the products or manually input the serial number below the QR code through T-keeper, you can add the device to the APP. Then you can check real-time data and historical data on the phone conveniently. If the temperature and humidity exceed or lower the alarm range you have preset, the main recording interface of the APP will turn red, which can notify you to adjust the abnormal situation in time. There are graphs of temperature and humidity changes in the APP. After ending the device on the APP, you can also export the PDF&CSV reports. From the graph and report, you can intuitively view the temperature changes in the PCB assembly workshop. That will help you get rid of the abnormal factors in the future.

And worth pointing out, that our Bluetooth wireless temperature and humidity sensor is also reusable. It can run for 200 days generally after the battery runs out, you can change it. It is cost-effective and environmental friendly.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文