It is essential for cocoa manufacturers to monitor the temperature and humidity levels within their cocoa bean fermenters and it is essential to carefully ferment cacao beans in order to achieve the optimal flavor profile and richness that define chocolate. Once the cacao pods have been picked and the beans have been scooped out, the beans are fermented in wooden crates or "fermentation boxes" for six days. A batch of 220 pounds of cacao beans is placed in these wooden crates along with the soy milk. Due to the large amount of fermentation, the temperature rises rapidly, usually to 48°C. The beans are fermented in these crates for six days.

The entire fermentation process is very laborious, but without close monitoring of the fermentation process, the beans cannot be made into high-quality chocolate. It is therefore essential that manufacturers have a real time temperature monitoring solution that can ensure the temperature and humidity inside the fermentation tanks are on the desired trajectory.

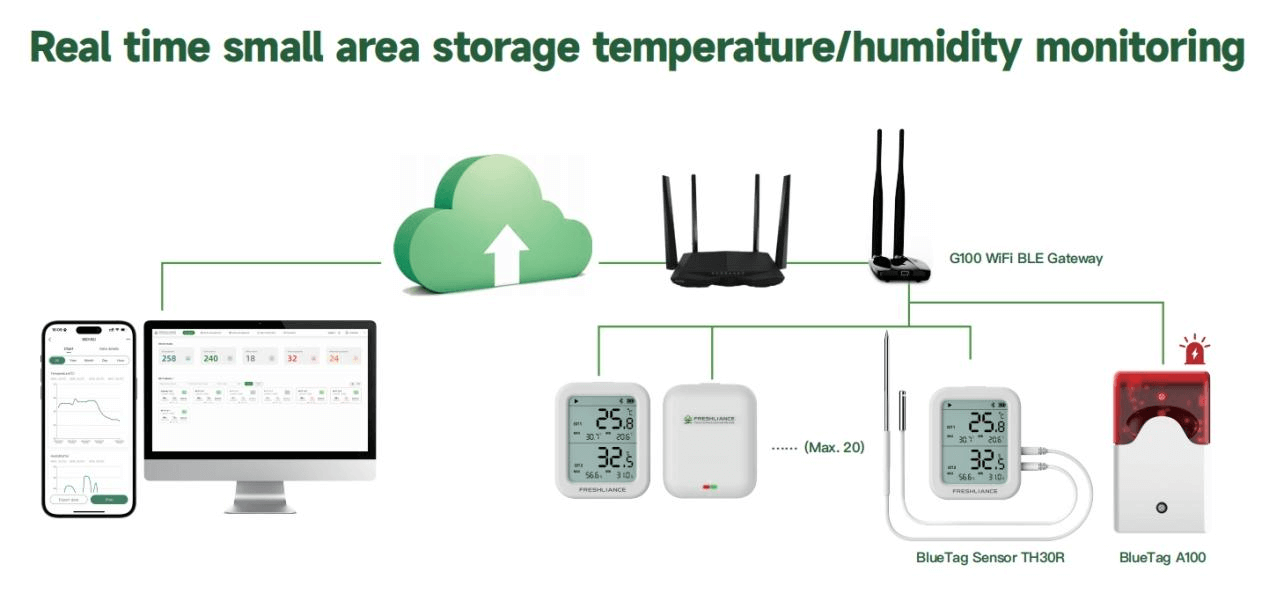

Our G100 Gateway and BlueTag sensors are suitable for this situation. Place the external probe inside each box and the main device of BlueTag sensor outside. Once the G100 Gateway uploads the data to the cloud via Wifi/4G, you will have real-time data on your computer or cell phone. You will also receive email or text alerts if temperatures are outside of normal ranges.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文