Bread

Whether you operate a small boutique bakery or a large baking factory, operating a bakery is no small job. Customers expect immaculate product quality and taste, whereas the authorities demand food-safe ambient conditions. Therefore, strict demands are put forward in the production of bread and baked goods.

General Recommendation

There are two important steps need monitoring the temperature and humidity of the environment in the production of baked goods: storage and dough proofing. For the baking ingredients stored at room temperature, the rule is to place them in an airtight container in an area that’s cool, dark, and dry. Ideal environments are between 50°and 70°F with a relative humidity level at or below 60 percent.

During the dough proofing process, yeast plays a critical role. To gain greater control over how yeast performs, bakers often use dough fermentation rooms or proofing cabinets, or proofers. Dough fermentation rooms require and temperature of 35 to 38 ℃ and relative humidity levels of at least 75 percent. Proofers have relative humidity levels of at least 80 percent to prevent skins from forming on the dough during the final proofing stages. In general, with the lower humidity, the crustier bread becomes as it bakes. Climate control technologies incorporated into proofing areas maintain the temperature and humidity levels necessary for the respective baked goods.

The Dangers of Not Monitoring the Temperature&Humidity

The conditions in which you store and handle baked goods are also important, as temperatures and humidity levels affect final products and their shelf life. Overly humid conditions soften crisp crusts, make crackers lose their crunch, or inhibit dough drying. If the area lacks temperature control, the goods will develop mold quickly. Overly arid conditions dry out goods that should be soft and moist, such as cakes and sweet rolls.

The Benefits of Monitoring the Temperature&Humidity

Whether in raw material storage, in the preparation of dough, or during the baking process–the product-specific requirements for temperature and relative humidity must be adhered to. Monitoring temperature and humidity is necessary for baking and ingredients storage to reduce waste and ensure the taste and quality of manufactured products.

Our Solution

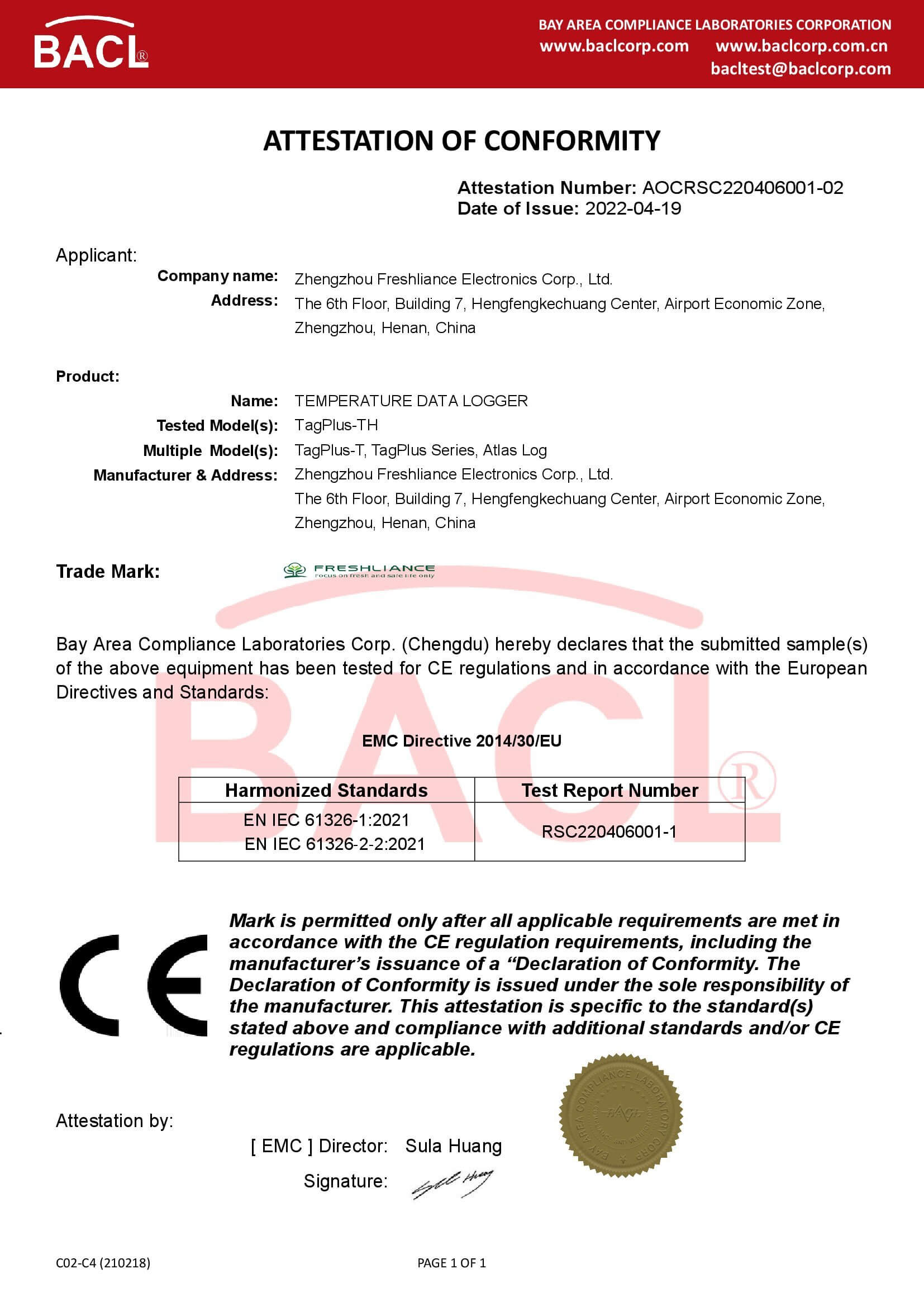

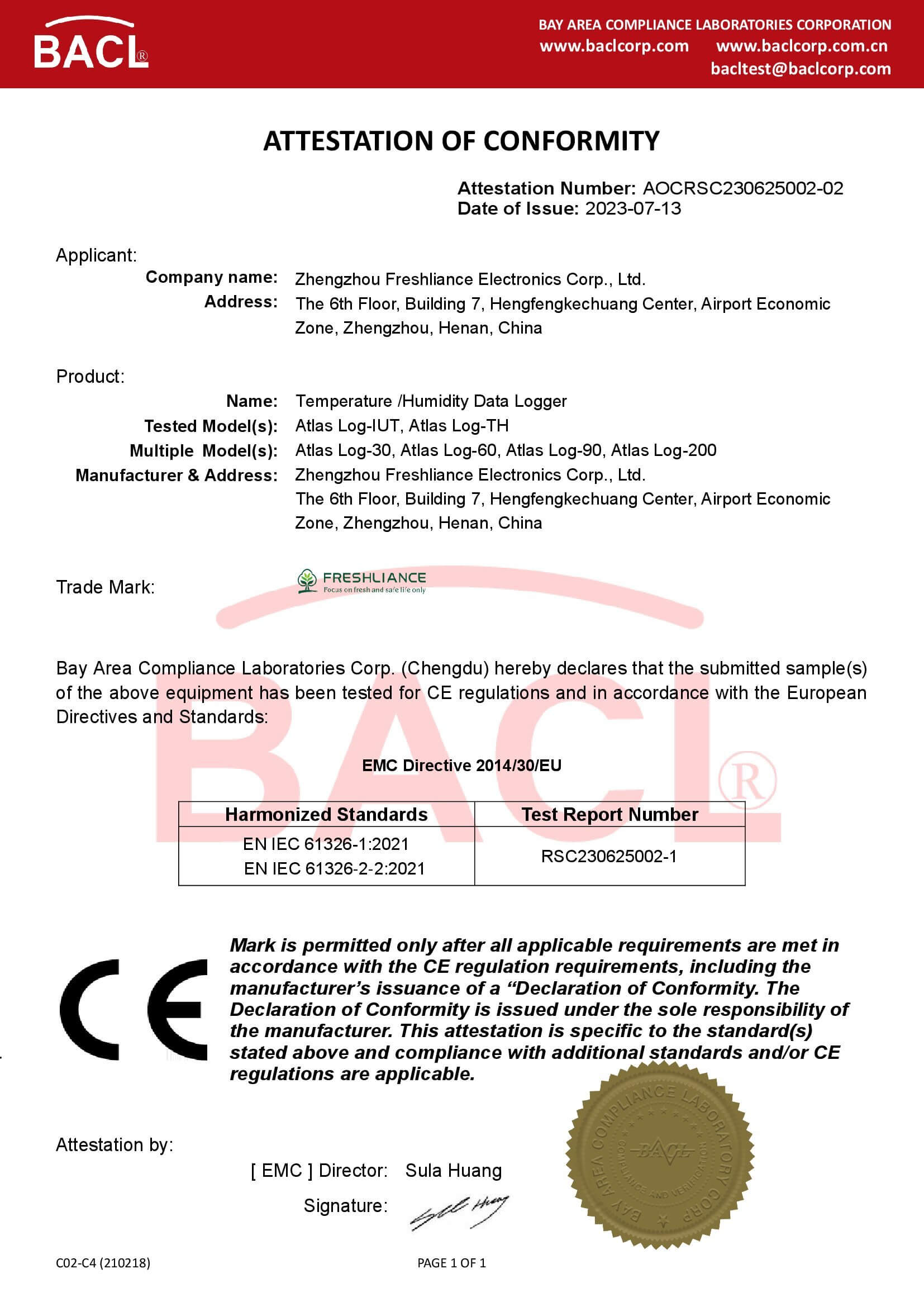

Our product BlueTag TH20 Bluetooth Temperature and Humidity Data Logger can greatly assist you to meet those strict requirements during baking and ingredient storage.

The BlueTag TH20 Bluetooth temperature data logger can measure temperature range from -30℃ to 70℃ and humidity range from 0~100%RH. Moreover, it features high accuracy of ±0.5℃. This wireless temperature and humidity sensor is definitely reliable in data accuracy.

BlueTag TH20 wireless temperature sensor can be attached to the refrigerator or the wall of the storage room. You can download the APP T-keeper in the Google Play app store, and connect this Bluetooth temperature logger to the APP. Then you can view real-time data and historical data from it.

You can preset the parameters of this wireless temperature data logger on the T-keeper APP, including the alarm range. If the temperature and humidity are out of this range, the main interface of the APP will turn red to remind you to adjust the temperature and humidity.

Our Cooperation Partners in Food Industry

Dole Food Company

Burger King

Contact Us

If you would like to learn more about temperature and humidity data logger for bread and other baked goods. Please get in touch with Freshliance. We’re professionals in temperature and humidity monitoring solutions.