Why Temperature Logging is Essential to Beer Cold Chain

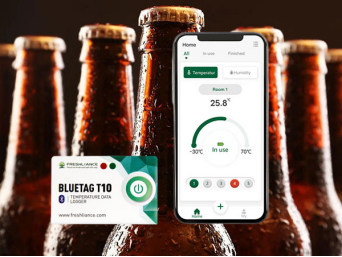

Improper temperature and temperature fluctuations is fatal to beer cold chain. BlueTag T10 bluetooth temperature sensor can be used to provide evidence that the cold chain has not been broken during transportation.

Thanks to improved distribution channels, today we can savor and enjoy beers brewed anywhere in the world. But how does the distribution chain affect flavor stability? How much does the flavor of a beer consumed hundreds or thousands of miles or kilometers away change compared to this same beer served at its place of origin? According to research, if the temperature is increased by 10°C, the chemical reactions will occur between two and three times faster. This is a concern when there is a large amount of beer in storage or travelling around the world; if the conditions are not adequate, it is easy to exceed 40°C temperature cycles. Depending on the speed with which the product moves, the probability of it going bad increases dramatically. The only solution for extending the stability of the product is to maintain the cold chain for as long as possible during its distribution.

Beer requires particular temperature, humidity/moisture and possibly ventilation conditions. As the optimum temperature for beer is between approx. 3 and 8°C, it is best transported as refrigerated cargo, to inhibit the metabolic activity of the microorganisms. At temperatures of below 2°C, chill haze occurs as a result of the precipitation of protein/tannin compounds, although this is reversible if caught early enough. If the chill haze lasts for a relatively long period, it becomes permanent and the beer becomes bitter. At temperatures of below approx. -3°C (depending upon alcohol content), ice expansion may occur. Cargo handling in frosty conditions in winter must therefore be performed very quickly. Beer must additionally be protected from relatively large temperature fluctuations, so as to prevent precipitation or haze. Excessively severe solar radiation may cause light flavor tainting. CO2 solubility reduces, so protection from excessive temperatures and temperature fluctuations must be provided. Recommended ventilation conditions: air exchange rate: 6 changes/hour (airing), if there is a risk of the formation of cargo sweat, which may lead, for example, to label detachment.

BlueTag T10 bluetooth temperature monitors can be used to provide evidence that the cold chain has not been broken during transportation. BlueTag T10 Bluetooth Temperature Data Logger is a small and compact wireless temperature data logger that has Bluetooth wireless transmission function. All parameters can be set by APP on the mobile phone. For the cold chain links such as storage, transportation, and distribution of temperature-sensitive products, it can realize the automatic monitoring, tracking, and recording of temperature in the whole process. You can simply download the T-keeper app, scan the QR code on the product, and the pairing will be successful immediately. Then you can configure the parameters of Name, Description, Sampling Interval, Start Delay, and Temperature Alarm Range. This shipping temperature recorder features a Built-in Japan-made smart thermometer sensor, the temperature is accurate to ±0.5°C/0.2°C(optional). This thermometer recorder can record a new and accurate temperature reading every minute. Within a 10m Bluetooth range, you can update and view the real-time temperature change every minute just by clicking the refreshed interface on your phone. You’ll receive a notification alert on your phone once the temperature is out of preset range. This bluetooth temperature recorder can help you effectively adjust the situation of your beer cold chain transportation in time. You also can print the QR code and stick it to the box, which can easily realize the reading temperature data without opening the box. When the logger is ended, the consigner and consignee can view the report nearly at the same time. And PDF and CSV reports are both available.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文