How to strictly monitor the food coldchain

Why set up a continuous temperature monitoring

Temperature is a key parameter for the marketing of sensitive products. As a professional, you have an obligation of result to make your products conform to the required quality and to respect the sanitary safety.

Ensure the safety of products

The cold slows down the chemical reactions, in particular those responsible for the degradation of food. Foodstuffs kept in positive cold must be kept at lower temperatures the more fragile they are. Cold makes it possible to inhibit, that is to say to stop or slow down the multiplication of micro-organisms sometimes naturally present in food.

Cold chain failure occurs when the food is exposed to a temperature higher than the maximum storage temperature for at least 30 minutes. The rupture of the cold chain will lead to a proliferation of sometimes pathogenic microorganisms and to risks of food poisoning.

Ensure product quality as specified.

A food is produced according to a specification that allows to have a constant quality of the product, identifiable by taste, texture, color. The sensory and nutritional qualities can be modified if the storage temperature is not respected.

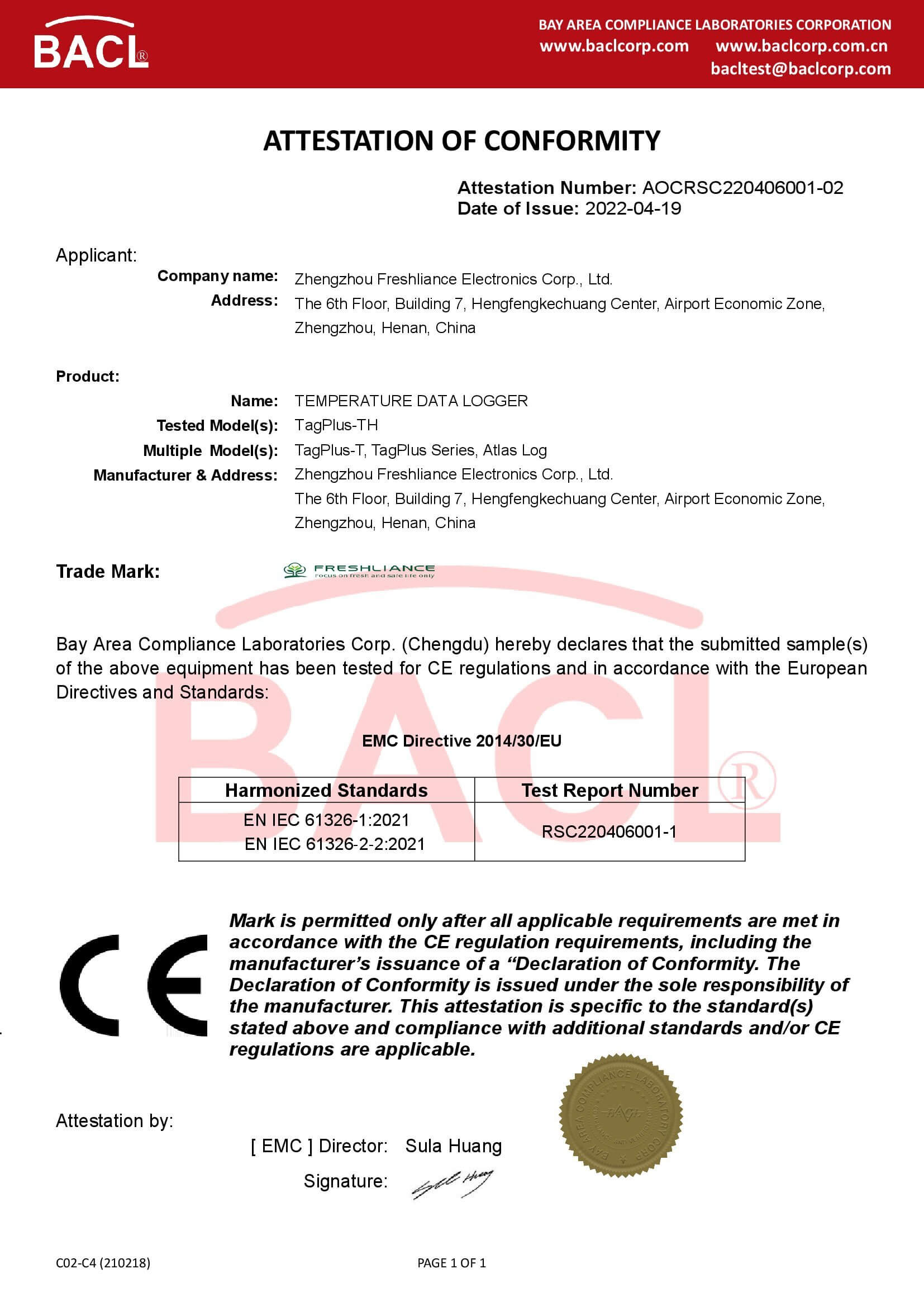

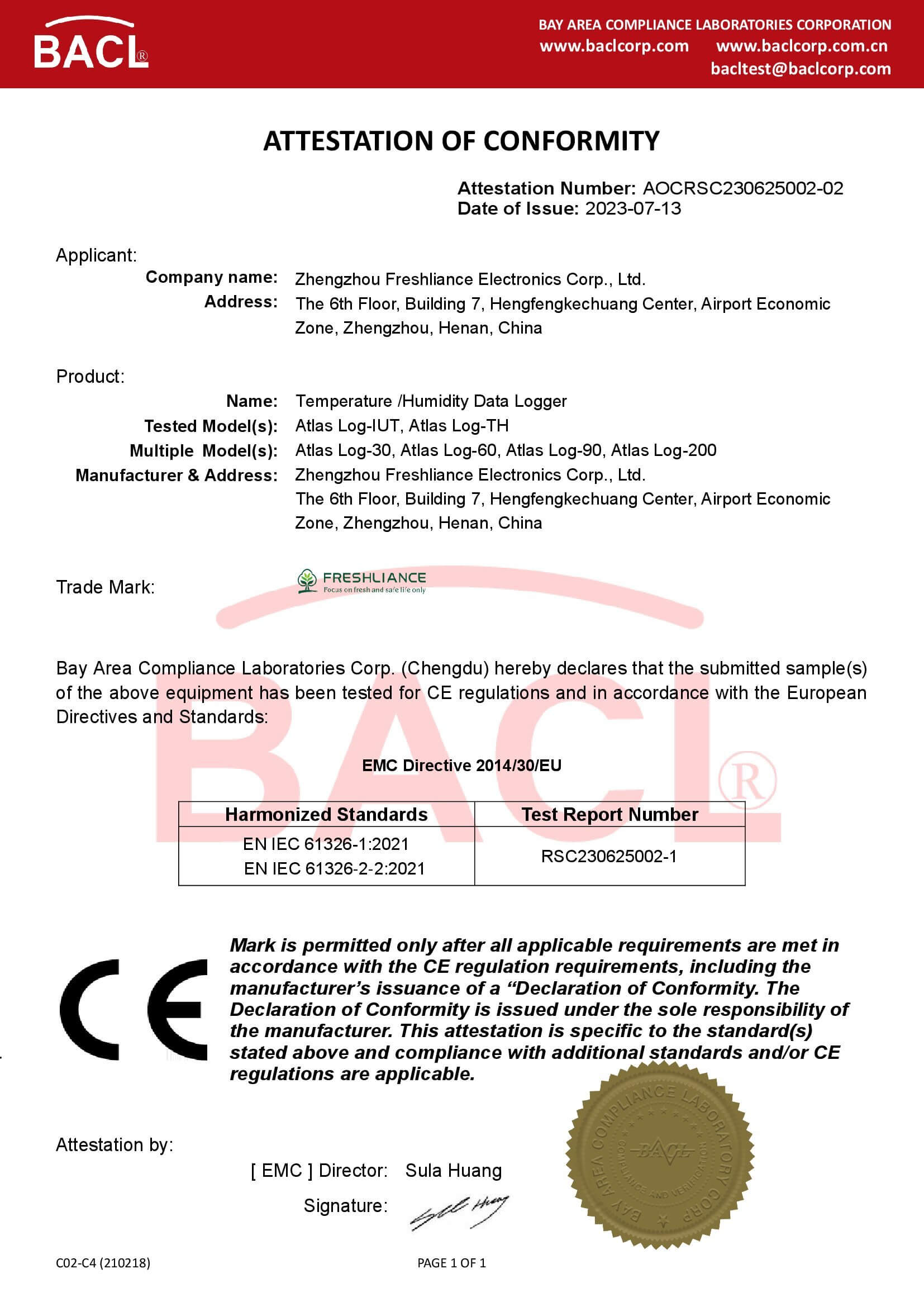

Responsible for regulatory compliance

In some cases, there are regulations that have to be enforced.

Heat-sensitive foodstuffs must be continuously refrigerated throughout the transport phase between the producer and the consumer and checked on receipt to prove that the temperature was maintained under prescribed conditions and there were no failures in the cold chain.

EU Regulation 37/2005 on temperature control in means of transport and storage of frozen food for human consumption provides for (Article 17) Frozen and frozen food storage rooms and ice-cream with a capacity of more than 10m³ must be equipped with appropriate automatic temperature datalogger for frequent and regular measurement, the air temperature to which these products are subjected.

These data loggers must comply with EN 12830, which lays down the technical and functional characteristics of temperature recorders intended for use on "means of transport, storage and distribution of chilled, frozen or frozen foods and ice cream"

Avoiding product loss due to a break in the cold chain

Breaking the cold chain can be avoided if you have an effective system that alerts you to the excursion.

This allows you to take immediate corrective action and avoid costly loss of product.

Where to set up a temperature monitoring system

ü Within production areas

ü During storage phases in warehouses, cold rooms, refrigerators or other kitchen or laboratory equipment

ü During transport under controlled temperature

ü On receipt of the delivered goods

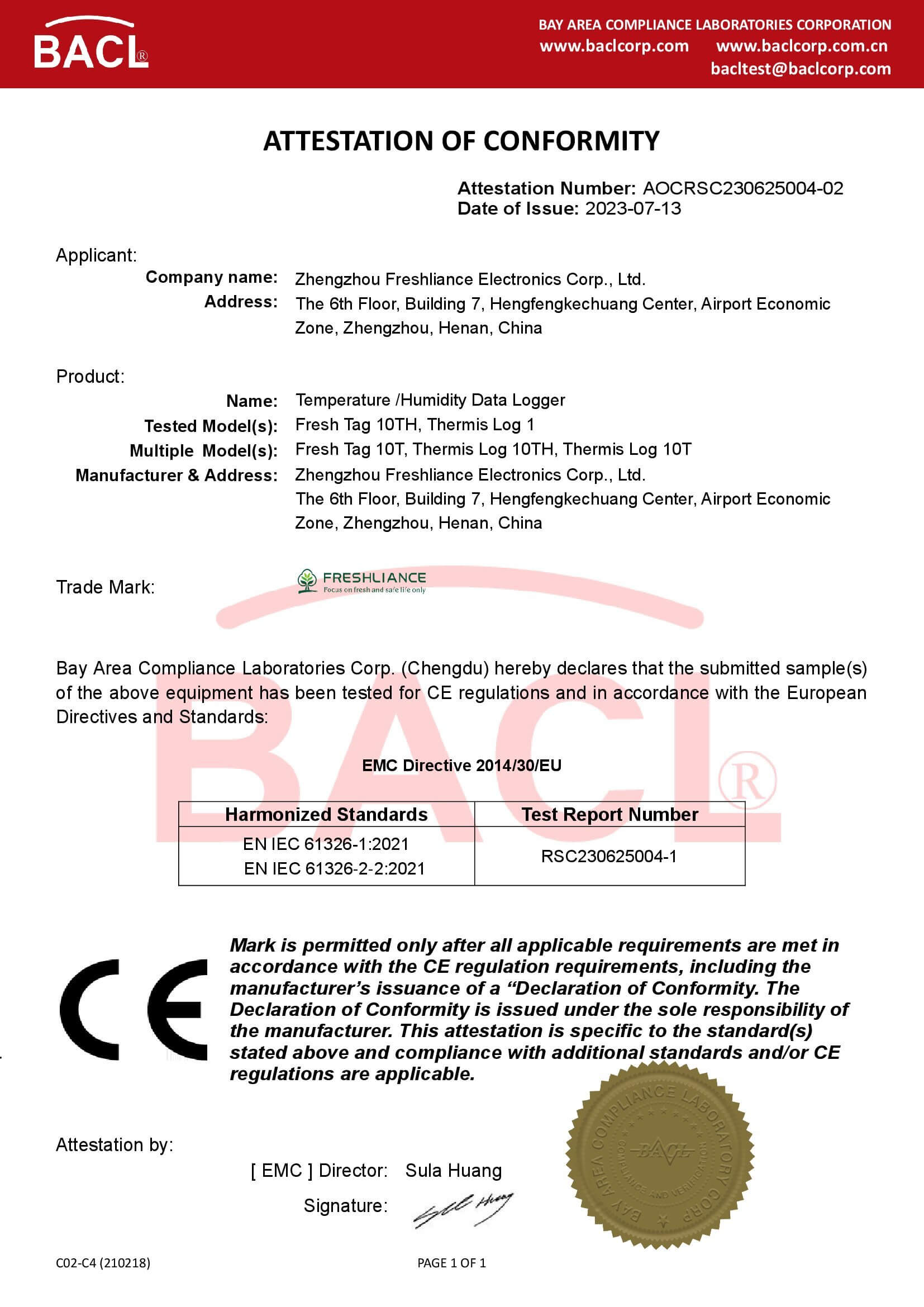

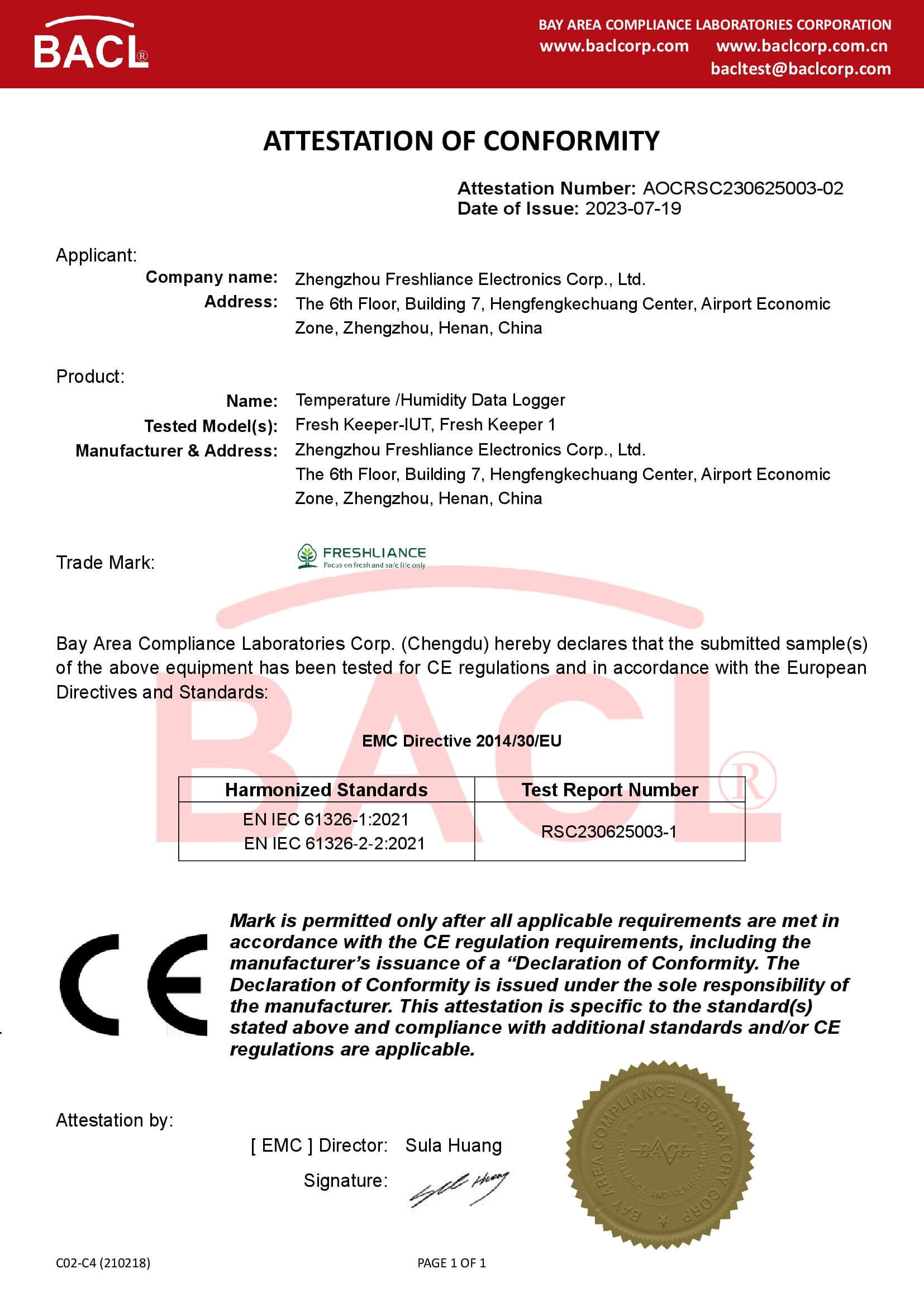

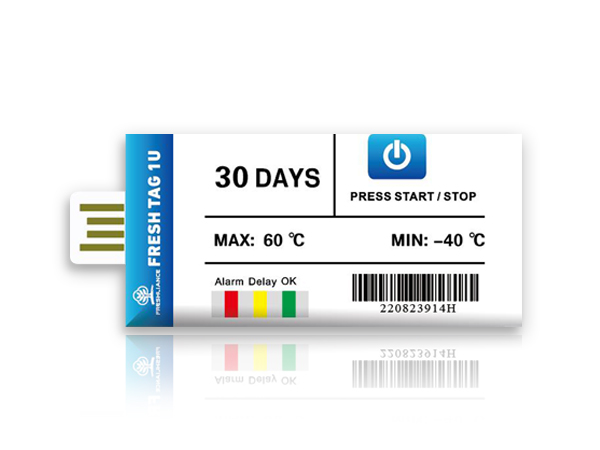

Fresh Tag 10 T is a single use temperature data logger. It is designed to capture and monitor temperature variations of sensitive products during transport and storage. They can be widely used in every stage of the cold chain, such as refrigerated containers, refrigerated trucks, cooling bags, cooling cabinets, medical cabinets, freezers and laboratories.

This data recorder series features a large LCD display for intuitive viewing. They can work for up to 120 days. You can configure the settings in our free configuration software. Once the journey is complete, by connecting the data logger to the PC, the PDF/CSV/PDF&CSV reports will be generated automatically without using the software.