Transport of dairy products

Dairy products are the most perishable commodities consumed in the world. The transport of dairy products is an essential element that must remain absolutely professional.

Carriers must ensure that milk is kept at a specified temperature during storage and transportation. Between 0 and 4°C for raw milk for consumption; for pasteurized milk, at a temperature defined by the producer. The GBPH (Good Hygiene Practices Guide) recommends a temperature not exceeding 8°C.

Considered a highly perishable food, milk must be transported in trucks to ensure a controlled and constant temperature under optimum hygiene conditions. The only exception is that, when milk and creams destined for industry are transported by tanker for a distance of less than 200 km, there is no demand for resources, but for results : the cold chain must be respected.

The transport of cream and yogurt must be done in compliance with the cold chain. Creams and yoghurts made from raw milk must be kept at a temperature between 0 and 4°C (or 6°C for 6 hours). Creams and yoghurts made from pasteurized milk must not be subjected to a temperature greater than 8°C (or 10°C during the same 6-hour period).

Understand the importance of preserving dairy products and find end-to-end refrigeration solutions. A professional cold logistics includes cold storage solutions as well as the operation of the road, rail and maritime network, thus guaranteeing the quality of dairy products from their loading to their delivery.

After understanding the importance of temperature for the transportation of dairy products, a solution must be found to monitor temperature.

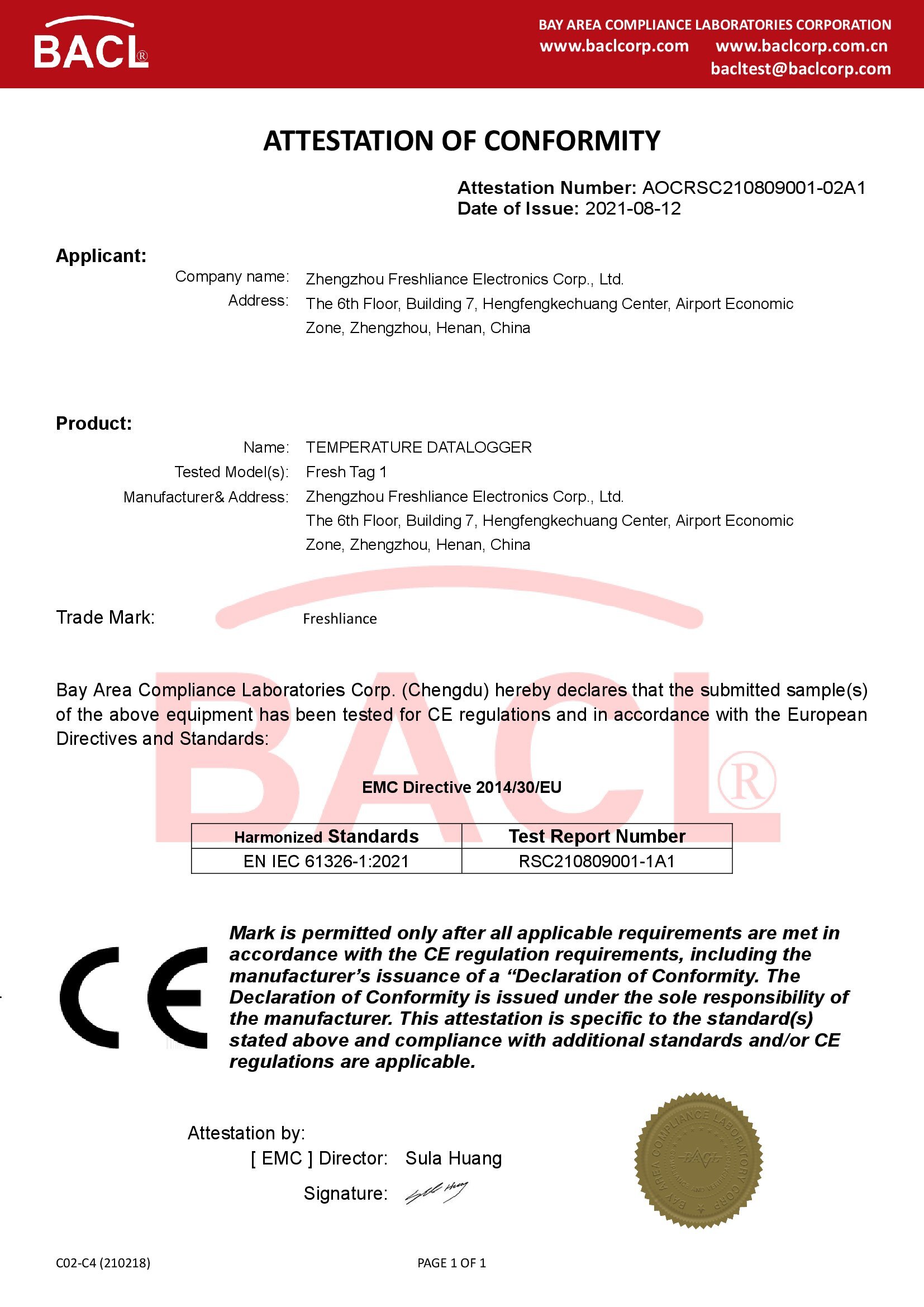

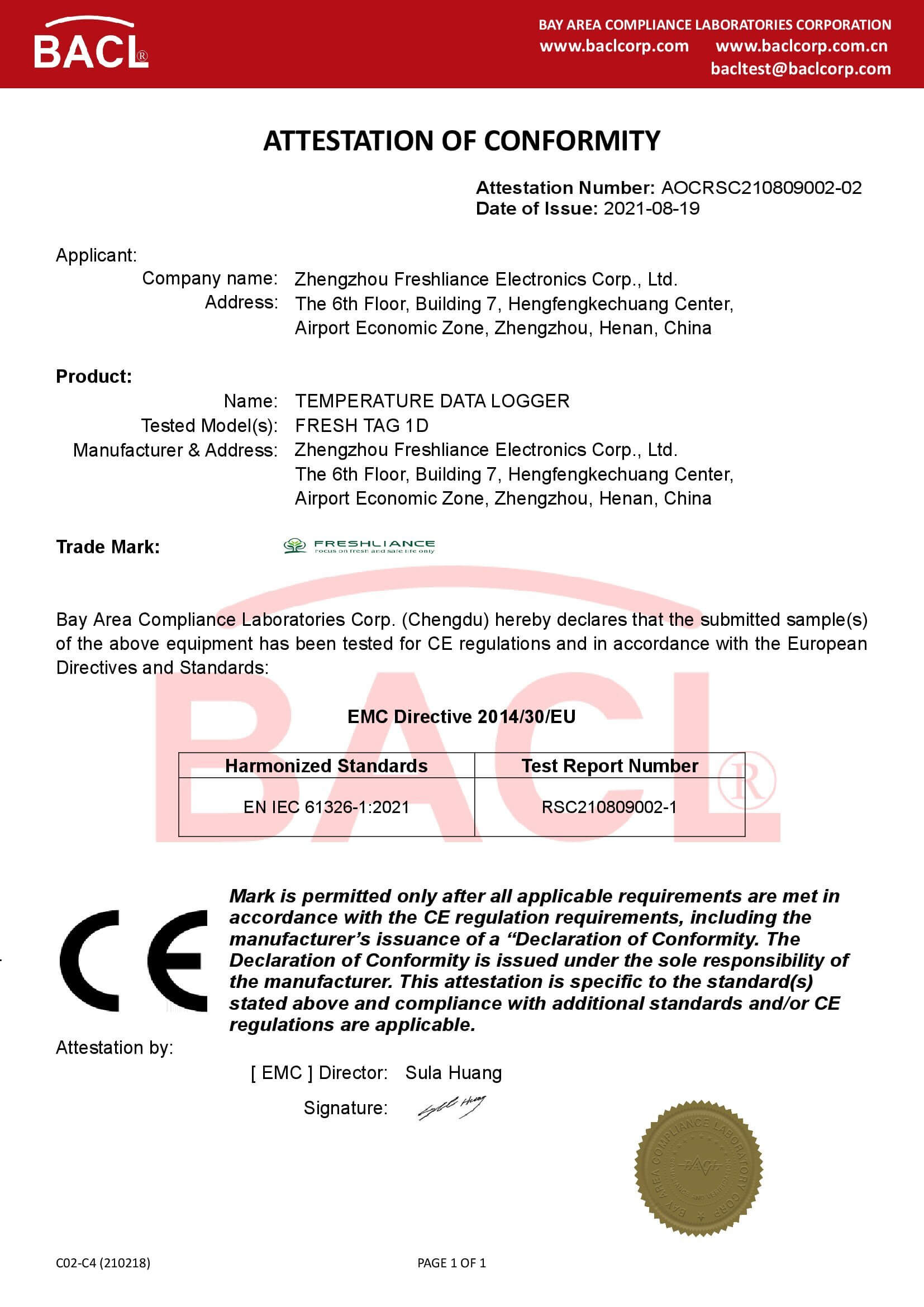

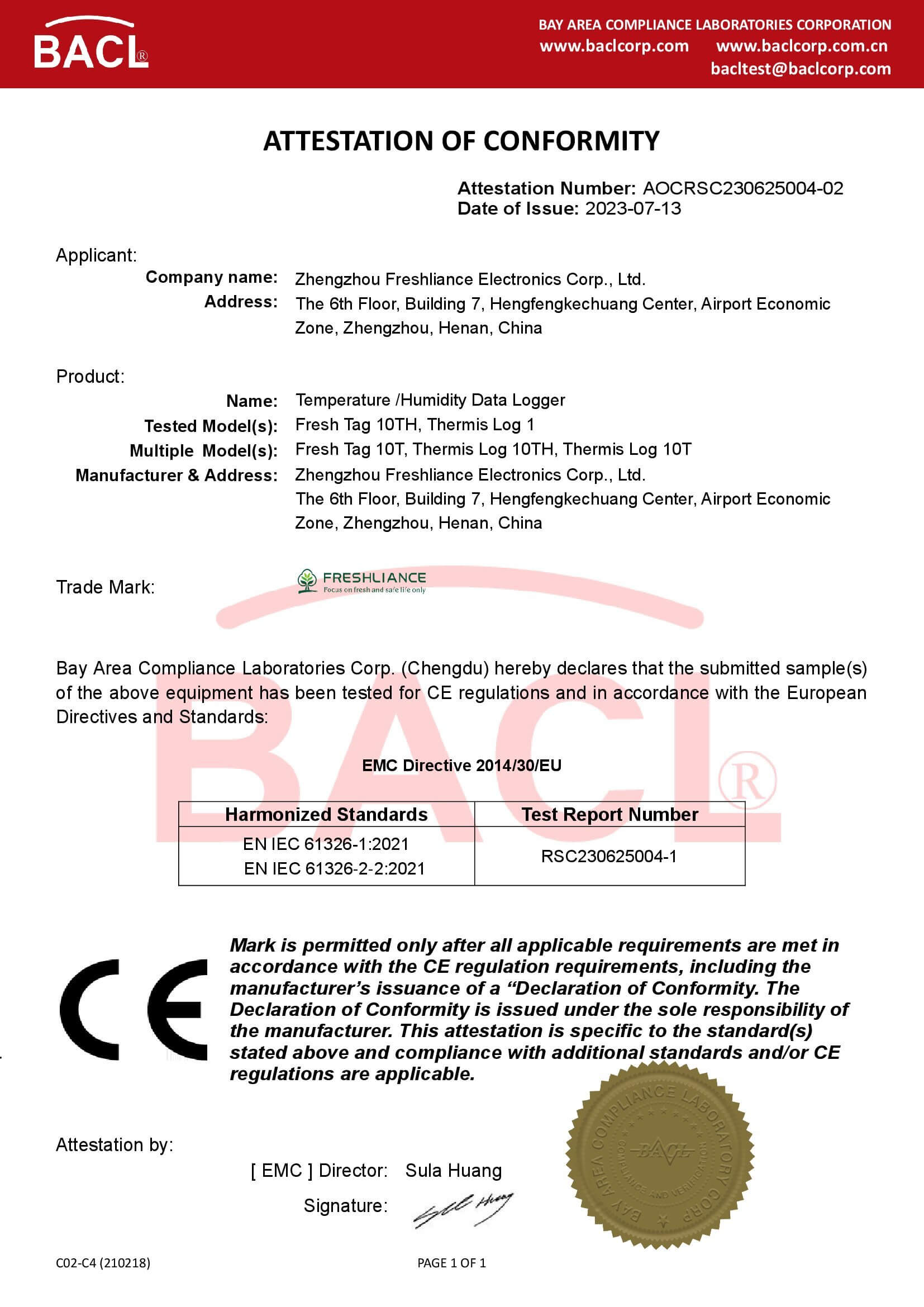

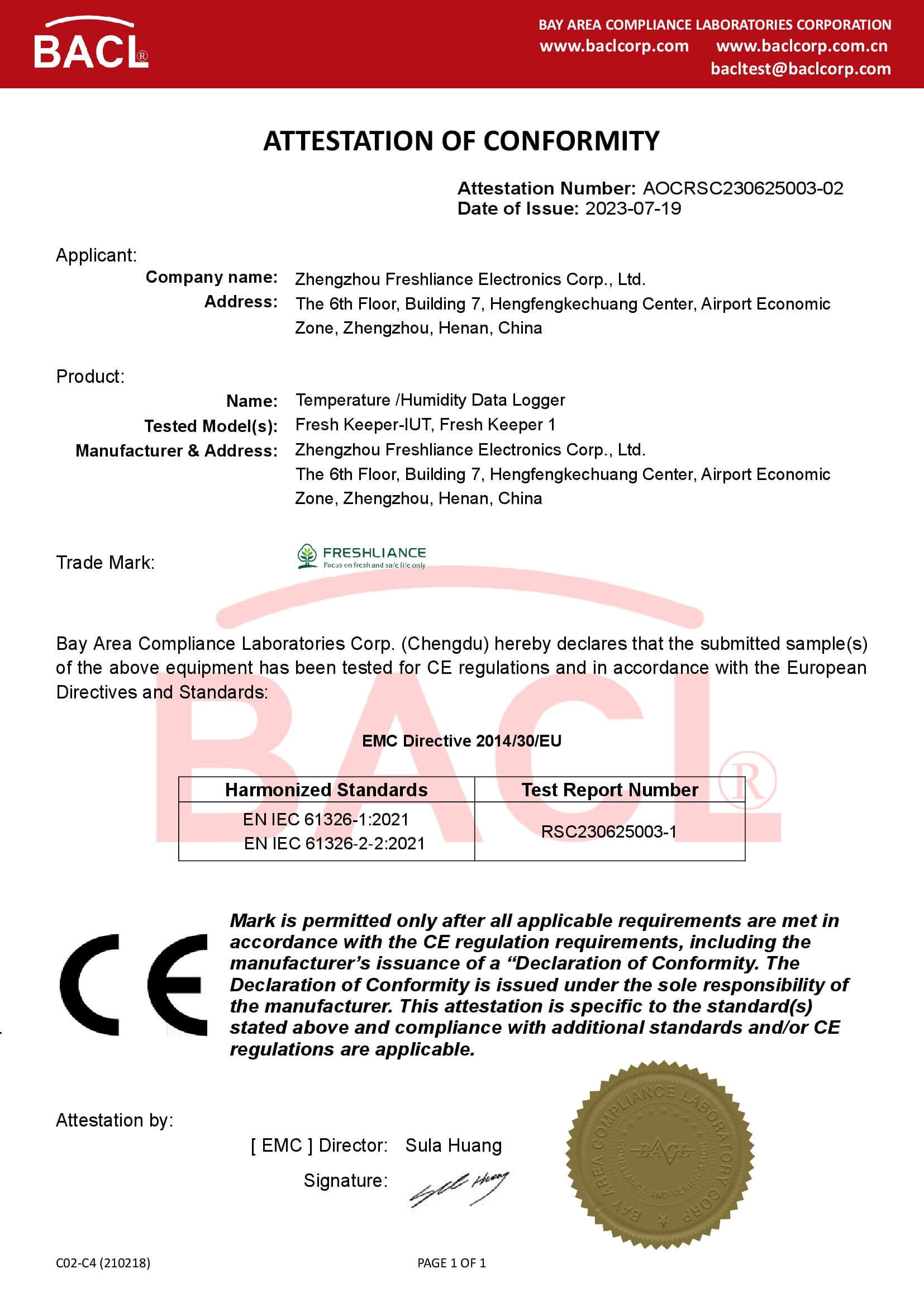

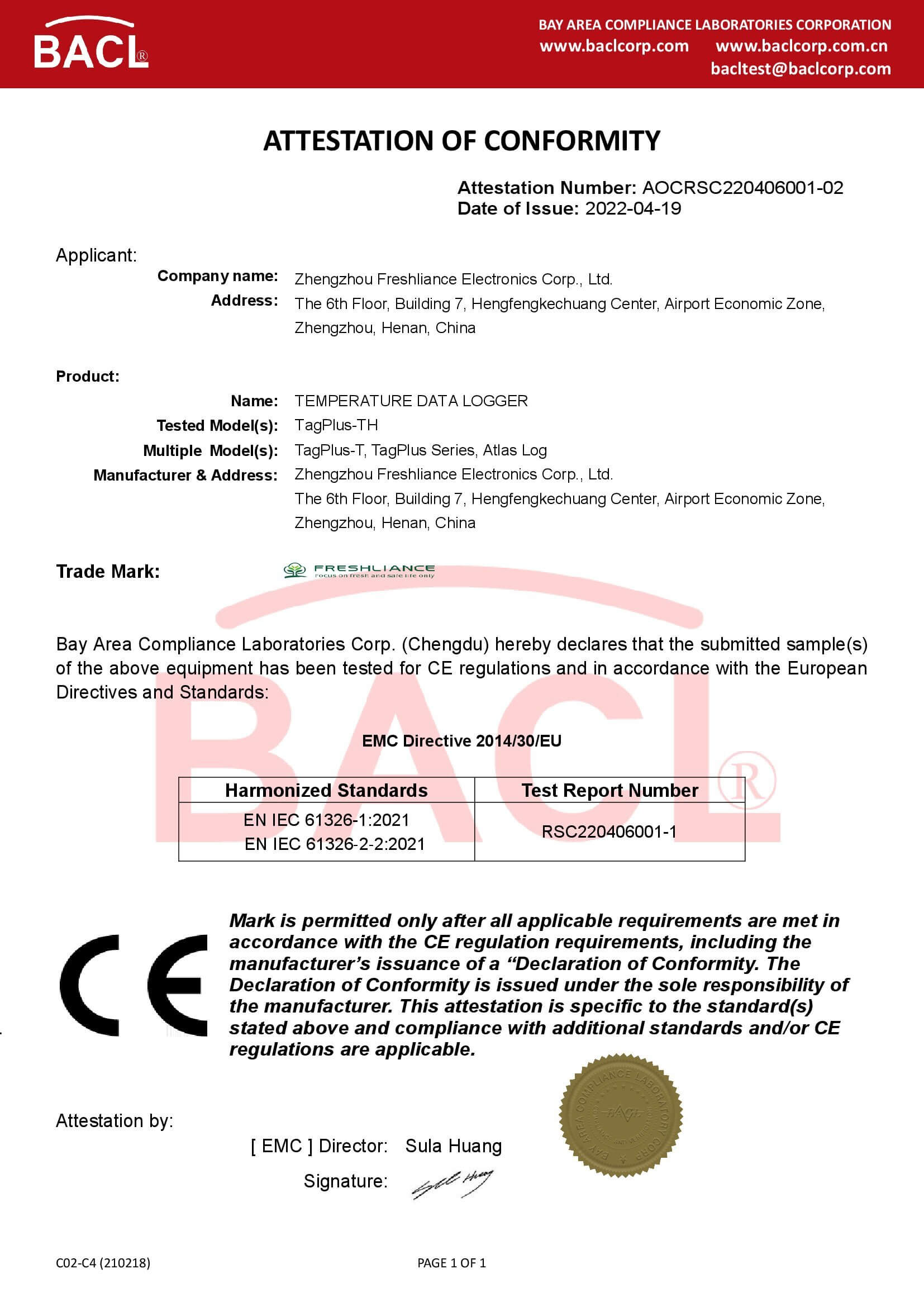

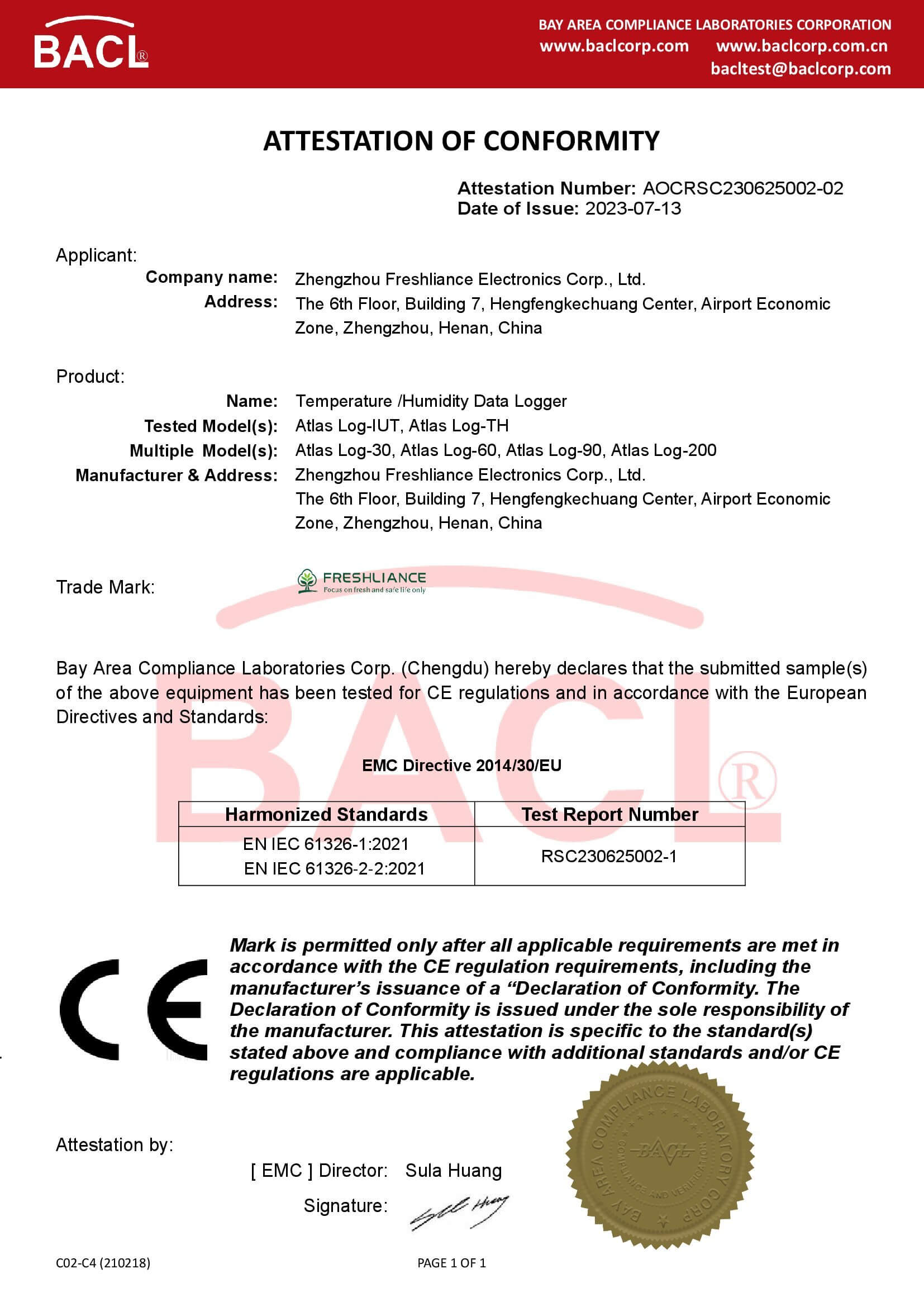

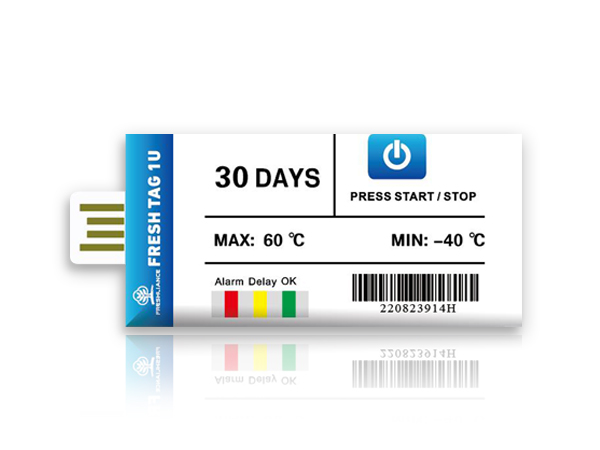

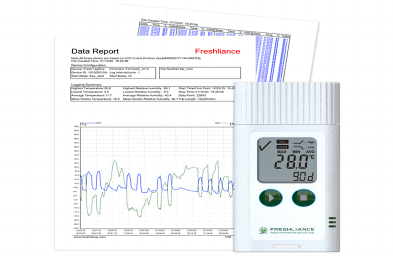

A USB data logger is sufficient for temperature control during the transport of dairy products. The TagPlus-TH is a reusable temperature and humidity data logger with LCD display for easy visualization of temperature data. In this device, settings can be set by a professional user before use.

Full travel history is recorded and uploaded to digital reports with summary data, graphs and tables. You can read the report directly on your PC. The temporary mode allows the data logger to continue operating once users have generated and read the temporary report. It is an ideal choice for monitoring and recording changes in temperature and humidity of dairy products during transport.