How Much Do You Know About Temperature Data Reporting and Management

Temperature data should be included in the existing monthly reporting procedure. At each supply chain level, supervisors should aggregate and analyse these data and generate a report that includes KPIs on supply chain and equipment performance; these KPIs can be used to guide decision-making. As they become more widely available, Internet, email and SMS data transmission technologies should simplify and enhance this process.

Monthly reports for cold rooms, freezer rooms, refrigerators and freezers should include:

The number of high and low alarm events per month for each piece of equipment. Where equipment is not fitted with an alarm device, record the number of temperature excursions outside the range +2°C to +8°C for refrigerated storage and

-15°C to -25°C for frozen storage;

A record of the number of doses and types of vaccine discarded due to heat exposure (as indicated by VVMs at or beyond the discard point), due to freeze damage (as indicated by shake-test failure) and due to breakage or expiry. Also record the storage location(s) where the vaccine losses occurred;

A list of actions taken to address alarm events and cold chain equipment failures during the current reporting period.

Monthly reports for transport should include:

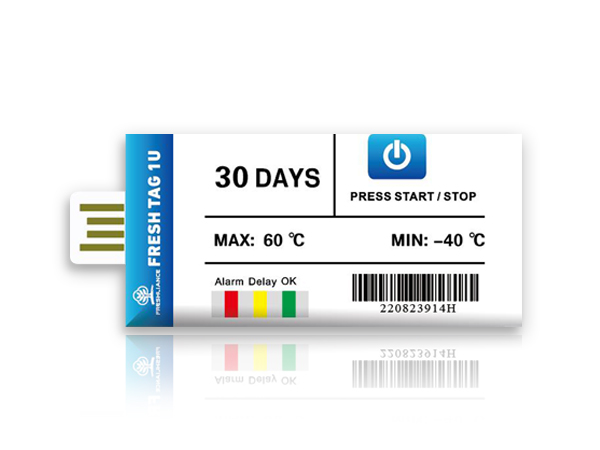

The number of high and low alarm events per month and the distance travelled for each refrigerated vehicle equipped with electronic event loggers or user programmable temperature loggers;

The number of freeze indicators triggered by low-temperature exposure for each refrigerated vehicle not equipped with logger devices;

The number of freeze indicators triggered by low-temperature exposure in cold boxes and/or vaccine carriers;

A record of the number of doses and types of vaccine discarded due to heat exposure (as indicated by VVMs at or beyond the discard point), due to freeze damage (as indicated by shake- test failure) and due to breakage and expiry. Also record the arrival location(s) where the vaccine losses occurred;

A list of actions taken to address these failures during the reporting period.

All reports should be reviewed and signed by senior supervisors or managers and kept for at least three years either on paper or electronically. Feedback should be given in a supportive way to help deal with problems and create incentives for ongoing reporting, maintenance, training and repair. In addition, the feedback on temperature monitoring should be linked to feedback on equipment performance and maintenance.