Steam Sterilization Verification with Rugged Temperature/Pressure Data Logger

Steam sterilization is the process of using the penetrating power of steam under high temperature and high pressure to achieve effective sterilization and finally make the sterilized products sterile. It is a key link in the production of pharmaceuticals, biological products, medical supplies, and equipment. During the sterilization process, specific temperatures must be obtained to ensure the microbicidal activity. The two common steam-sterilizing temperatures are 121℃ and 132℃. These temperatures (and other high temperatures) must be maintained for a minimal time to kill microorganisms.

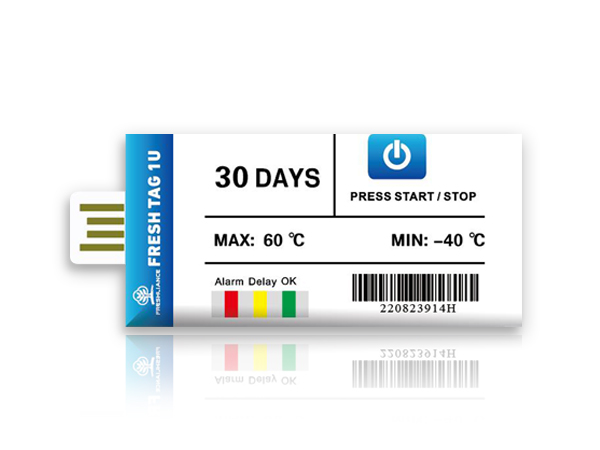

Freshliance’s rugged temperature/pressure data logger is designed for hard environment monitoring, with temperature ranges of 90℃~+60℃/-40℃~+125℃/-50℃~+150℃ and pressure ranges of 0-500PSI customizable, and comes with S316 stainless steel case, submersible and resistant to high temperature. It can be directly placed in the cavity of the sterilization equipment to monitor temperature, pressure, etc. After data monitoring, take it out and let it cool to room temperature. The data can be accessed by connecting it to a computer via typeC port. It is a scientific and effective verification of sterilization equipment.