Vaccine transportation requirements Pharmaceutical Single-use Temperature Data Logger

Pharmaceutical cold chain transportation is regarded as the pinnacle of the cold chain industry. The vaccine cold chain has a higher threshold compared to the general fresh food cold chain. Vaccine preservation requires strict temperature requirements, requiring storage at -50--15°C for refrigeration and 2-8°C for refrigerated storage. Temperatures need to be monitored and recorded regularly throughout storage and transportation.

The vaccine cold chain has strict logistics requirements for hardware, software, full control, and relevant certifications. If the temperature of a vaccine is too high or too low during any stage of the process, the efficacy of the vaccine may be impaired, and the result is irreversible. Since vaccines require a full cold chain, all cold storage, cold rooms, refrigerated containers, and qualifications of vaccine distributors need to be in accordance with World Health Organization (WHO) specifications. There are also specific WHO guidelines for the management and storage of each vaccine. According to experts, short-haul transportation of vaccines exposed to temperatures outside the recommended range results in a loss of approximately $34 billion per year.

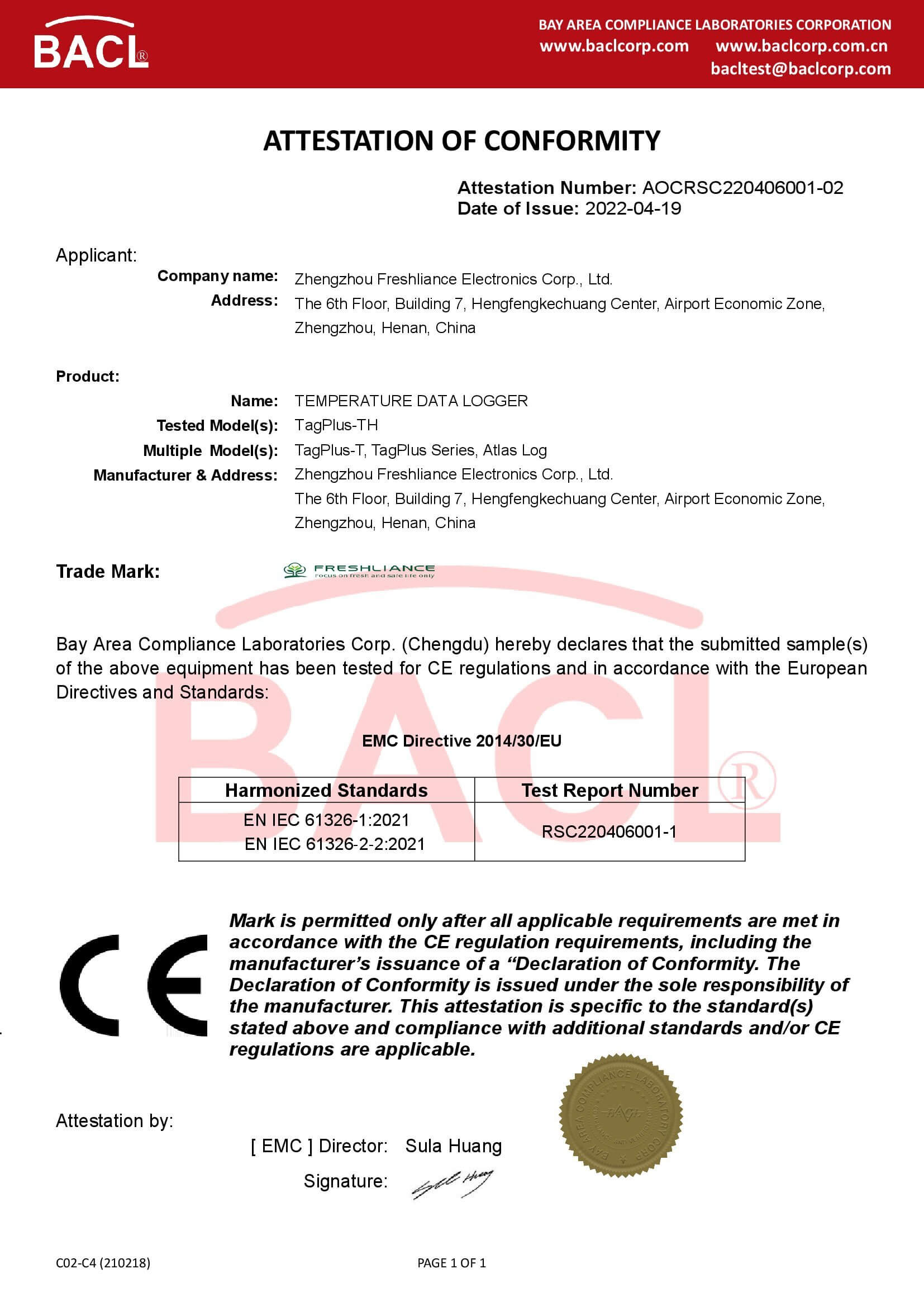

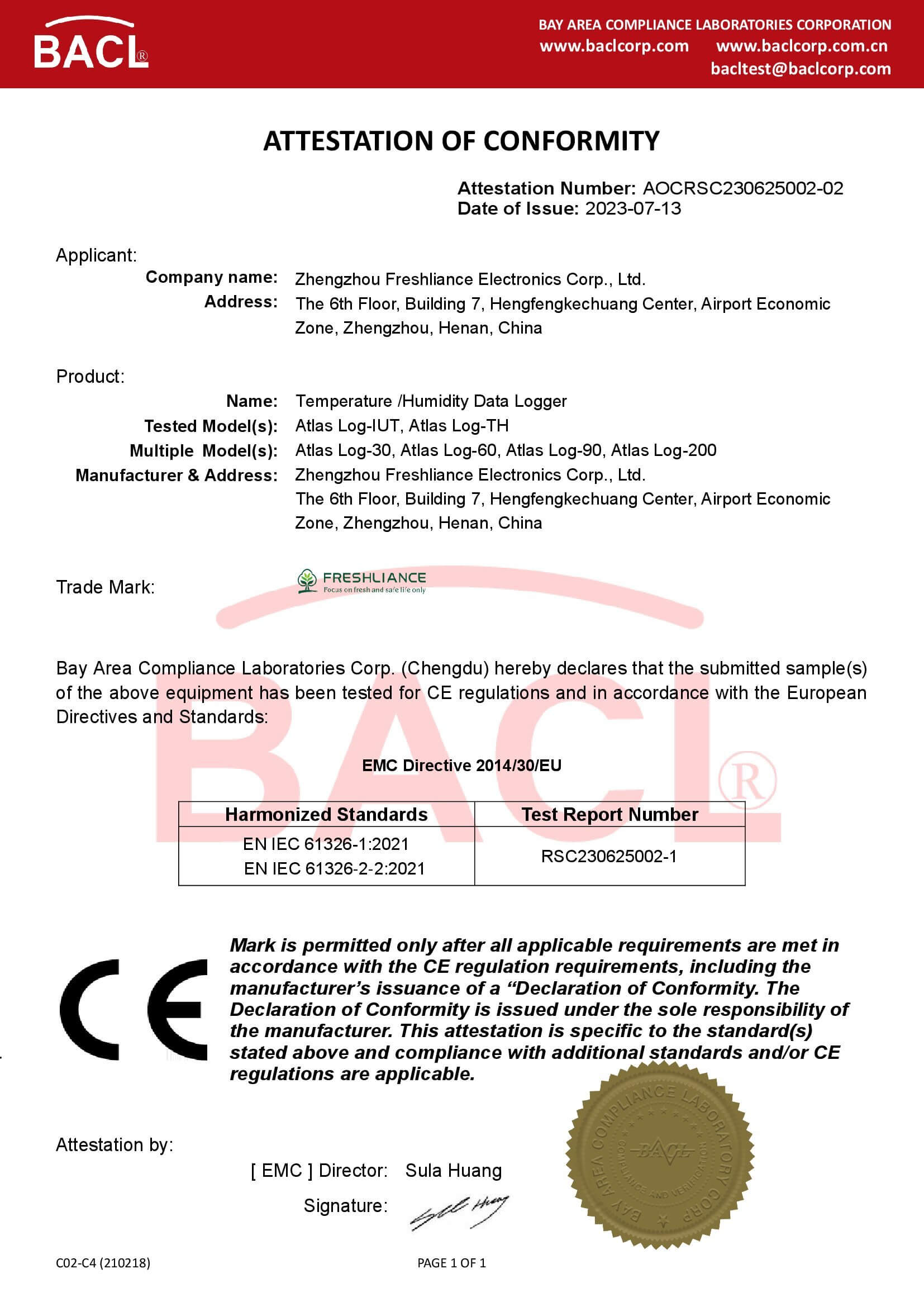

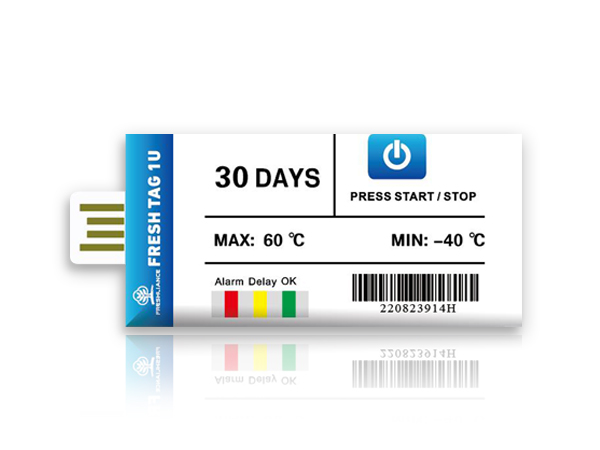

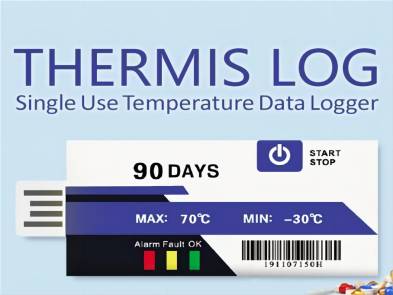

Thermis Log Single-use Temperature Data Logger is specially designed for the pharmaceutical industry. With ±0.5℃ at full range (-30℃ to +70℃) accuracy, this logger is ideal for logging temperature-sensitive shipments, especially vaccine shipments. This temperature logger is low cost, easy to operate, takes up little space and generates non-modifiable PDF data reports by plugging the logger into a PC. We offer a variety of models with different features (7, 15, 30, 60 or 90 days available) to meet the specific needs of each application. The Thermis Log disposable temperature logger is ideal for pharmaceuticals, food, life sciences, freezers, medical cabinets, fresh cabinets, freezers, laboratories, vaccines and protein products.