Importance of data logging during transportation

Temperature-controlled products are widely transported locally, nationally and worldwide, requiring logistics professionals to maintain the cold chain efficiently.

Why is temperature data recording and analysis essential to maintaining compliance standards for the transport and storage of goods?

Fast-growing global demand.

As the world becomes increasingly connected, with digital applications and e-commerce, distance is no longer a deterrent. It is now easy for customers to order fresh/frozen/medicinal products... and have them delivered directly to their door.

This factor, combined with population growth, makes the situation very clear: perishable goods are purchased by many more people than ever before. From the moment a product leaves the production line to the moment it is consumed, it can transit up to 14 times, which is just as many times as the risk of a break in the cold chain.

This means that logistics operators need to optimize processes with accurate and reliable cold chain data recording. The transportation of any perishable goods requires cold chain storage.

Why is data collection essential in cold chain transport?

Cold chain transport reduces the risk of deterioration of perishable goods due to high temperatures, high humidity levels or prolonged exposure to light. Without refrigeration technology and data monitoring solutions to check that transport or storage conditions are appropriate, we wouldn't be able to guarantee the quality of products such as fresh produce, frozen foods, medicines and vaccines, and so on.

Data logging is essential for moving these goods from point A to point B, as it enables operators to ensure that all transport and storage conditions comply with environmental conditions.

A data logger should also be able to alert people when a fridge or freezer is not within the acceptable temperature range. Then the problem can be solved (by repairing the equipment or moving the stock to another cold store) before it damages the products.

Which temperature recording solutions are most suitable for cold chain logistics?

Temperature measurement devices are also essential for logistics operators, cold storage platforms or temperature-controlled transport. To make day-to-day work and decision-making easier, Freshliance measuring devices are the ideal companions for the cold chain.

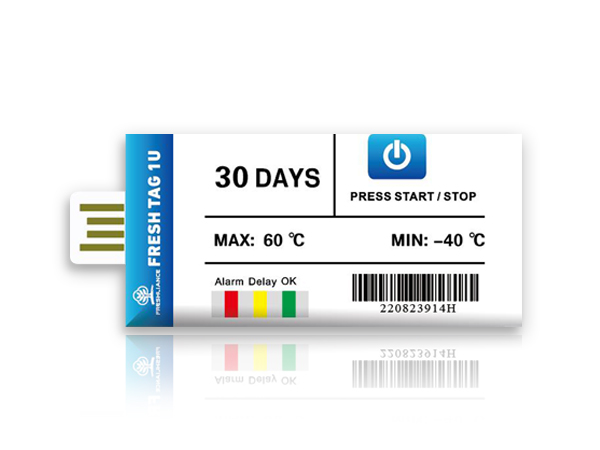

The Fresh Tag 10T is ideally suited to the transport of sensitive goods, and can be used at all stages of the cold chain, including refrigerated containers, refrigerated lorries, refrigerated bags, refrigerated cabinets, doctor's surgeries and freezers, etc.

This series of data loggers features a large LCD screen for intuitive display. They can operate for up to 120 days. Parameters can be configured using our free configuration software. Once the trip is over, by connecting this logger to the computer, PDF/CSV/PDF&CSV reports will be generated automatically without using the software.