The Secret to Success in Yogurt Making—Use of Temperature Data Logger

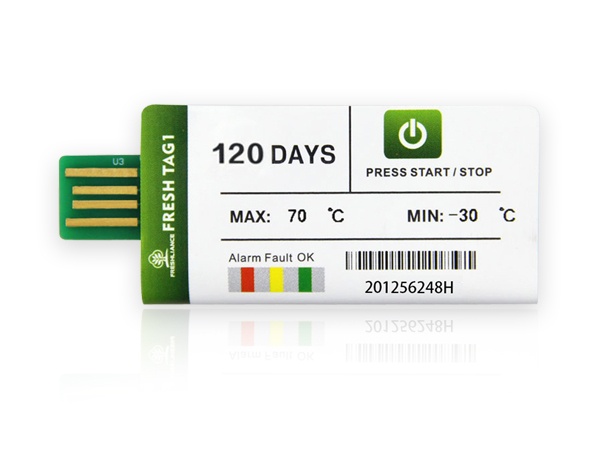

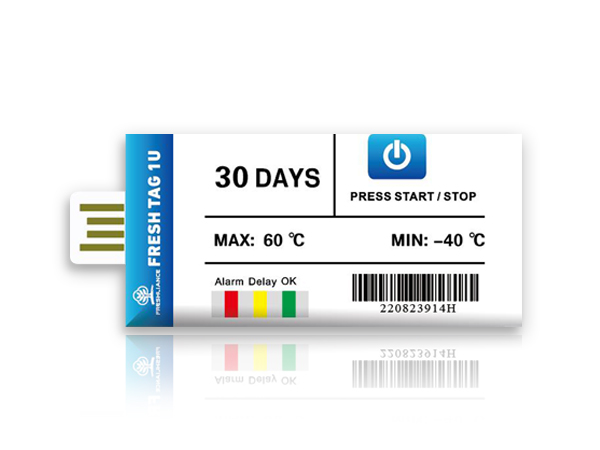

Freshliance COEUS-UEX ultra low temperature data logger can measure temperature up to 200℃. It can work well to help make yogurt successfully.

Yogurt is the sought-after health food today. In most grocery stores and supermarkets, the yogurt section has taken over the dairy aisle. Yogurts can be high in protein, calcium, vitamins, and live culture, or probiotics, which can enhance the gut microbiota. These can offer protection for bones and teeth and help prevent digestive problems. Low-fat yogurt can be a useful source of protein on a weight-loss diet. Probiotics may boost the immune system. Yogurt is a fermented milk product. Thus, the success of yogurt-making is closely related to temperature.

Here’s how yogurt is made. Let’s take a look at how temperature works in it. In order to prevent the deactivation of the bacterial cultures needed in yogurt production, milk is pasteurized at 185°F for 30 minutes or 203°F for 10 minutes prior to the addition of the cultures. The high heat also denatures the whey proteins, which allows the yogurt to form a more stable gel. Then adjust the milk composition, blend the ingredients and homogenize it. The milk is then heated to 200°F for 10–20 minutes, depending on the desired thickness of the yogurt. Holding it longer will result in a thicker yogurt. The mixture is then cooled rapidly to 112–115°F. At this point, the warm mixture is inoculated with the live bacterial culture. The mixture is incubated for 4–7 hours at 105–115°F. The bacteria used in making yogurt are thermophilic and this is their optimal temperature range; they are killed above 130°F and do not grow well below 98°F. Yogurt will become firm when a pH of 4.6 is reached. Incubating the mixture any longer will result in increased acidity and a more sour taste. When the desired pH is reached, the yogurt is cooled to around 45°F to end the fermentation process. For set-style yogurt, fruit is added to the bottom of the cup and the inoculated yogurt is placed on top of the fruit prior to fermentation. For Swiss-style yogurt, fruit is mixed with the yogurt after the fermentation and cooling steps. The yogurt is then packaged; at which point, it should be refrigerated at 40°F or lower.

Freshliance COEUS-UEX ultra low temperature data logger can measure temperature range from -90℃ to +200℃, this can totally cover the temperature range of the yogurt making needed. This ultra low temperature sensor is combined with a main body and a external probe. This temperature and humidity data logger can be used in the pasteurization, heating, cooling and inoculation, incubation and cooling steps of yogurt making. Just put its external probe to the liquid, then you can see the detailed real time data from its large LCD screen. This ultra low temperature data logger features a high accuracy of ±0.5℃(-90℃~+70℃)/±1℃(others). Temperature humidity recorder with high accuracy would help you get rid of the risk of concern of failure for yogurt making. Moreover, before start, you can download our free configuration software and preset up to 6 alarm points. When the yogurt is incubating for 4–7 hours, you don’t have to stay with them all the time. Once the temperature is out of the alarm range, the temperature data logger with probe will give sound and light alarm. You’ll find abnormal situation immediately and adjust it in time.

Freshliance Electronics Co. specializes in the development, manufacture, and sales of temperature and humidity data loggers, environmental monitoring, online tracking and recording systems. Contact us to get the temperature and humidity monitoring solution tailored for you.