The Importance of Temperature Monitoring and Tracking in Vaccines Transit

To ensure good storage and distribution practices for vaccines, the effective and well-managed temperature monitoring and record-keeping procedures in vaccines transit are quite crucial. These procedures help to ensure that:

Vaccine quality is maintained throughout the vaccine supply chain;

Vaccine is not wasted due to exposure to heat or freezing temperatures at fixed storage locations or during transport;

Cold chain equipment performs according to recommended standards;

When problems arise, they are rapidly detected and corrective action is taken.

The temperatures to which vaccines are exposed must be monitored, recorded and reported throughout the vaccine supply chain, from the manufacturer’s point of origin to the point of vaccination. This provides documented evidence of the temperatures to which products have been exposed during storage and transport; it also provides a means of detecting cold chain equipment failures and other operational problems so that they can be rectified.

Responsible personnel need to know the correct storage conditions for all vaccines in their country’s schedule. They must also know how to do the following: use the appropriate temperature monitoring devices, recognize and respond to temperature excursions, record temperatures, and take corrective action when problems occur. To achieve these outcomes, countries should develop suitable policies and standard operating procedures (SOPs) and provide adequate training, tools, supervision and resources to ensure that these policies and procedures are properly implemented.

The availability of new technologies, especially the vaccine vial monitor (VVM), 30-day temperature recorder (30 DTR) and advances in information and communication systems, provide great opportunities for supply chain improvement.

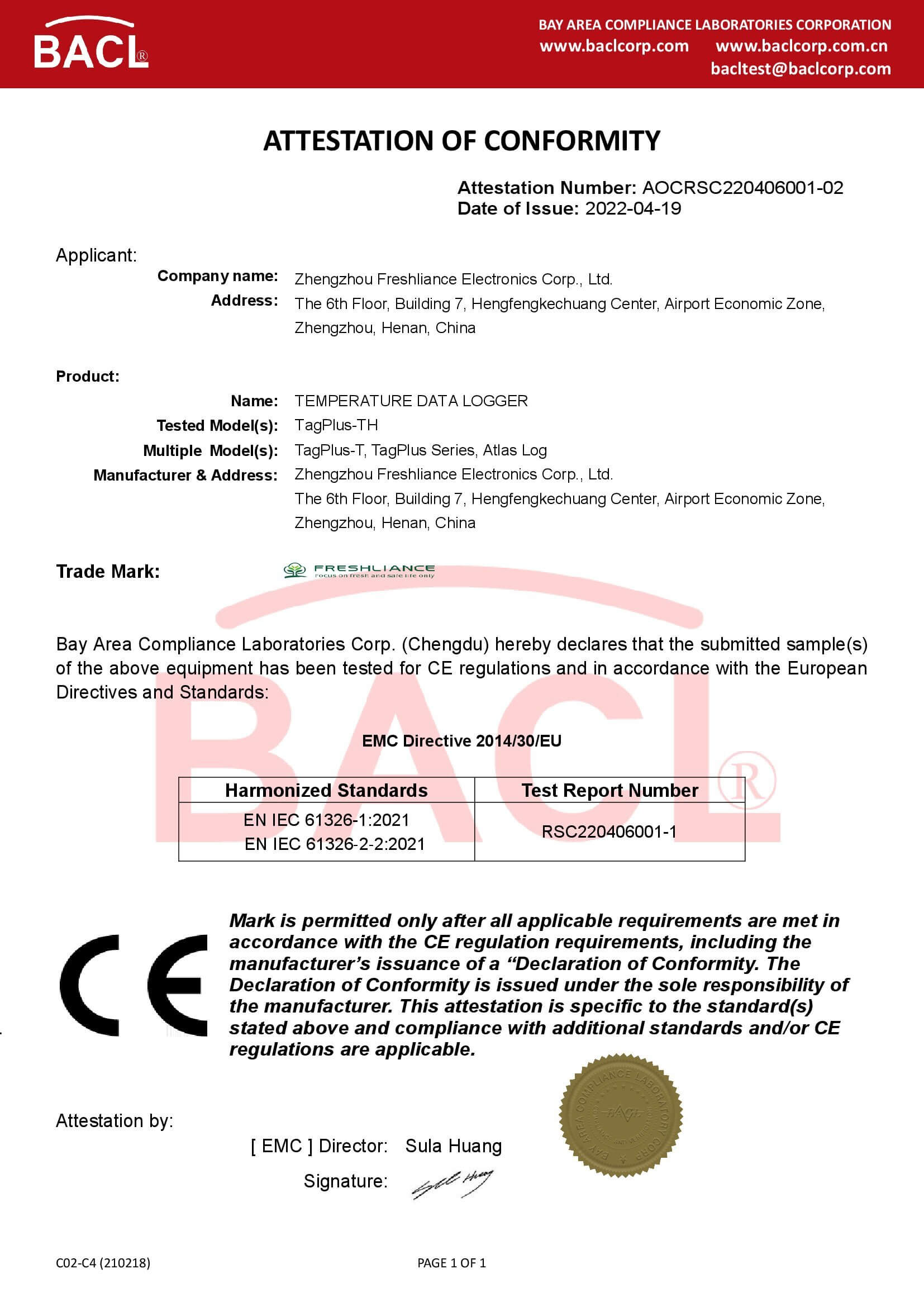

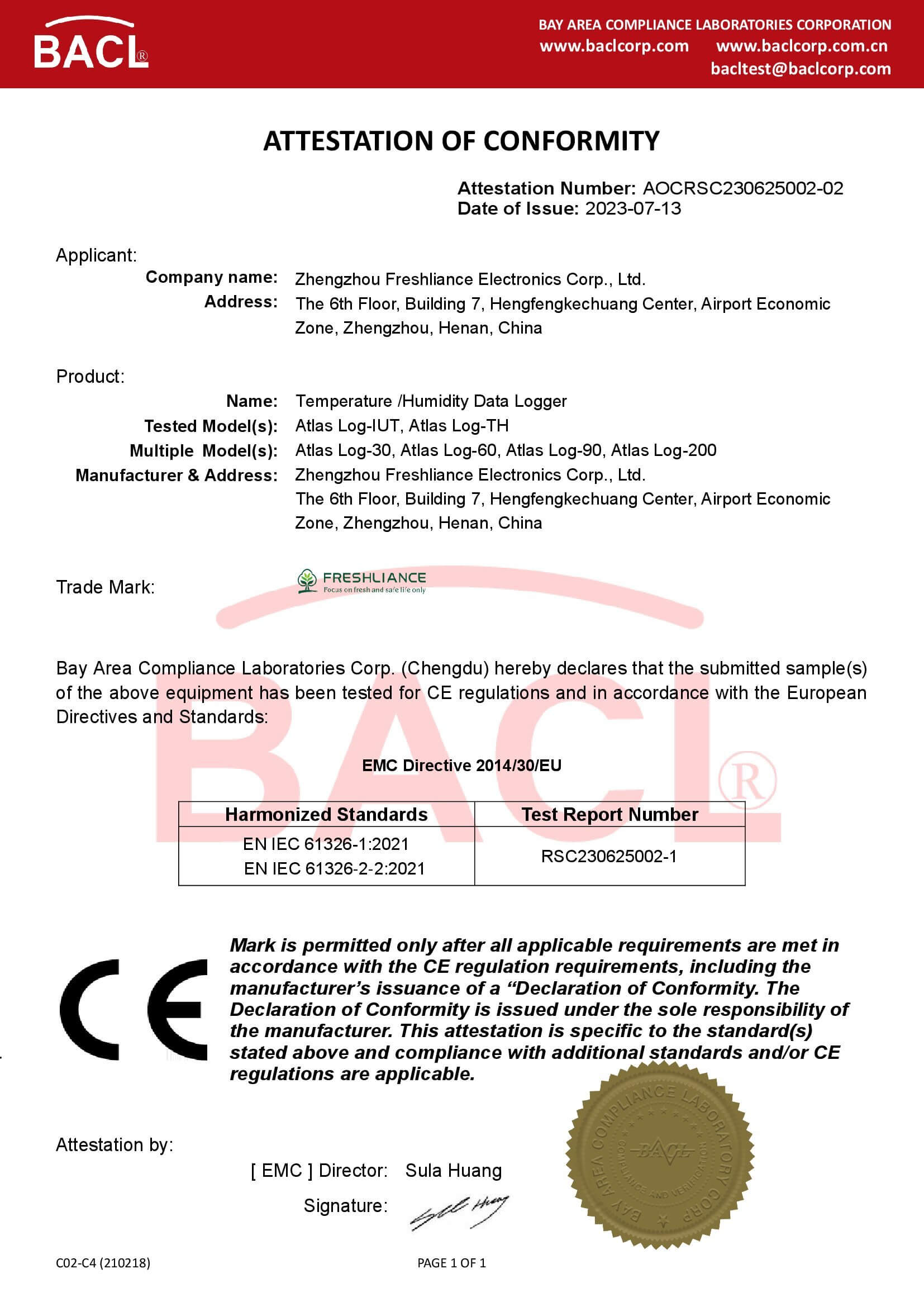

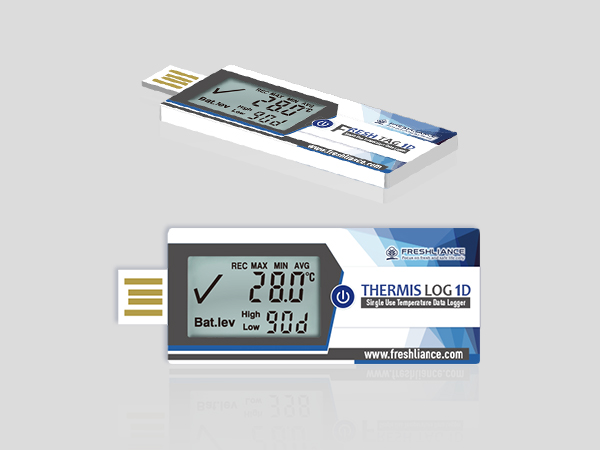

Freshliance provides you with different kinds of tmperature recorders, which can meet your highest standard requirement for monitoring vaccines transit. Take Thermis Log 1D as the example, it has the following features:

Free from software uploading, read the data by PC at any time;

PDF readout, irreversible and true recording;

High accuracy for Pharmacy transportation;

Logger can be used even at low temperature;

Multi options (7, 15, 30, 60 or 90 days available).

Freshliance Thermis Log 1D Single Use USB Temperature Dataloggers adopts Japanese made sensor, with truly 0.4℃ accuracy, which is suitable for pharmaceuticals, food, life science, cooler boxes, medical cabinets, fresh food cabinets, freezer or laboratories which need high accuracy request. Freshliance provide all kinds temperature data logger or temperature and humidity data logging solutions to make sure every change in whole cold chain solution will be traced and recorded irreversible, PDF Logging, CSV temperature history, on line IOT logging in any format are available.