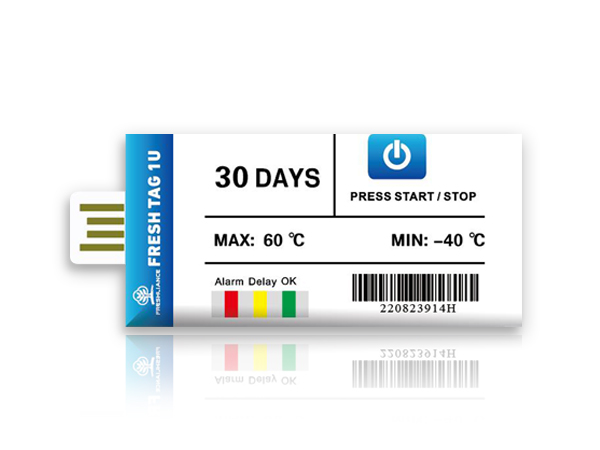

The Important Role of Temperature Data Loggers for Cold Chain Logistics

As people have higher and higher requirements for the quality of life, especially the preservation of fresh fruit, the importance of temperature data loggers for cold chain logistics has been highlighted. It is specifically manifested in the following aspects:

The use of temperature data loggers for cold chain logistics to detect fresh fruits and vegetables can ensure food quality and establish a company’s brand image. In a sense, the brand of an enterprise determines the destiny of an enterprise. Therefore, the temperature data loggers for cold chain logistics meets the higher level of "green food consumption" demand.

The use of temperature data loggers for cold chain logistics can reduce the deterioration and loss of fresh food; with a clear temperature record, it can be determined whether the environmental temperature of the medicine exceeds the standard, and unnecessary losses caused by estimation and speculation can be reduced.

The temperature data loggers for cold chain logistics also meet the safety supervision requirements of food and drugs. Temperature is a very important parameter related to food safety. According to the requirements of the HACCP system, in addition to inspecting the shelf life, outer packaging, and appearance of food, raw material procurement must also strictly inspect the internal temperature of the food and the continuity of the temperature during transportation.

The temperature data loggers for cold chain logistics can meet the requirements of medical treatment and planned immunization. In order to ensure the effectiveness of immunization, the entire process of vaccines used for planned immunization from production, storage, transportation, distribution to use should be equipped with complete refrigeration equipment to keep the vaccines in the specified temperature environment at all times to ensure that the efficacy of the vaccines is not affected. The supporting equipment of the cold chain includes low-temperature cold storage for storing vaccines, ordinary cold storage, vaccine transport vehicles, refrigerators, cold boxes, cold backpacks, and monitoring systems. The cold chain system of existing vaccines is not optimistic and lacks a temperature monitoring and recording mechanism, such as the effective temperature data loggers for cold chain logistics.

To sum up, the end-to-end real-time monitoring and recording of temperature in all links of the cold chain is an important part of food and drug safety. At the same time, higher requirements are also put forward for the technical means of the temperature data loggers for cold chain logistics.