Keep Kiwi Fresh, Make Life Healthy

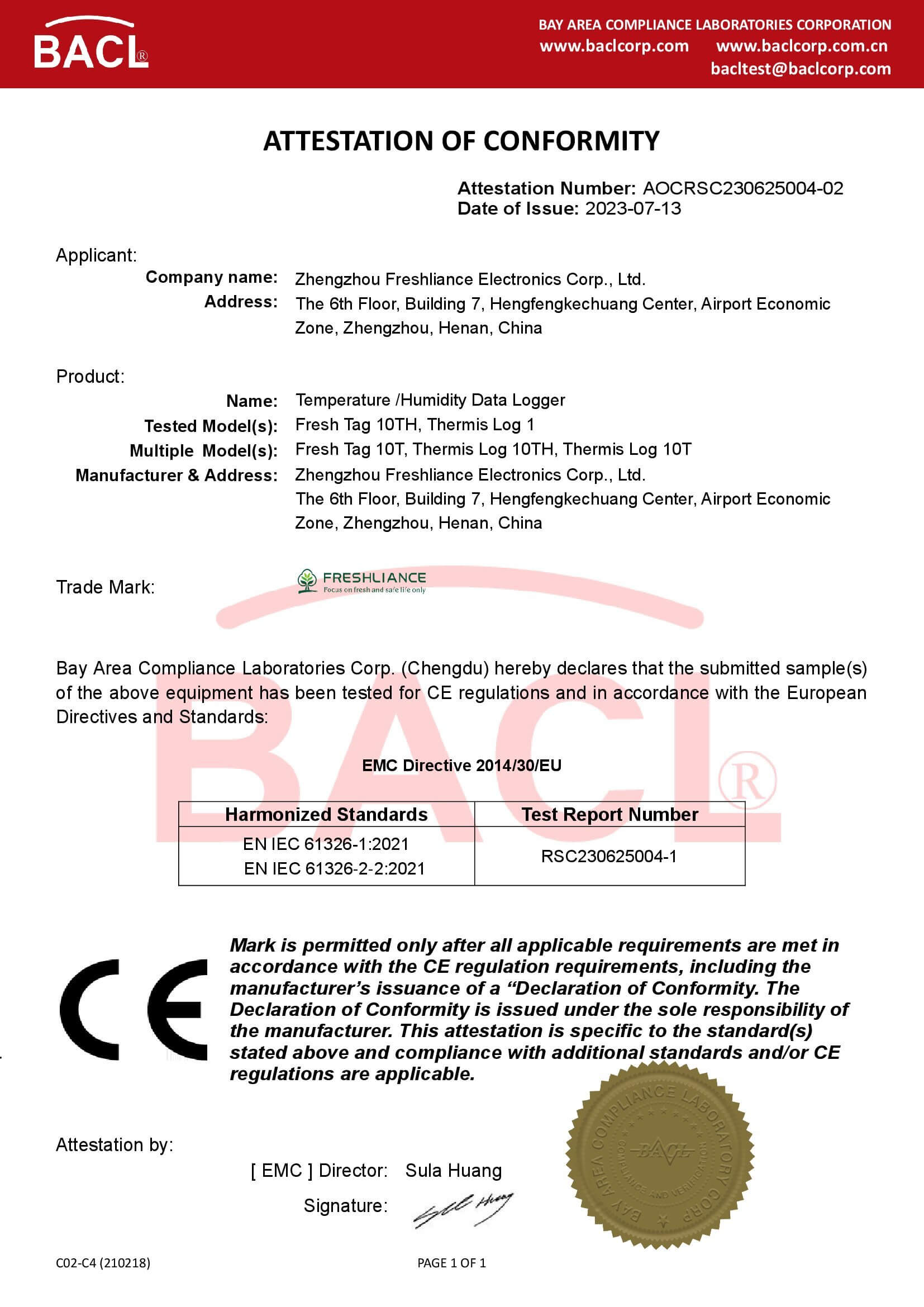

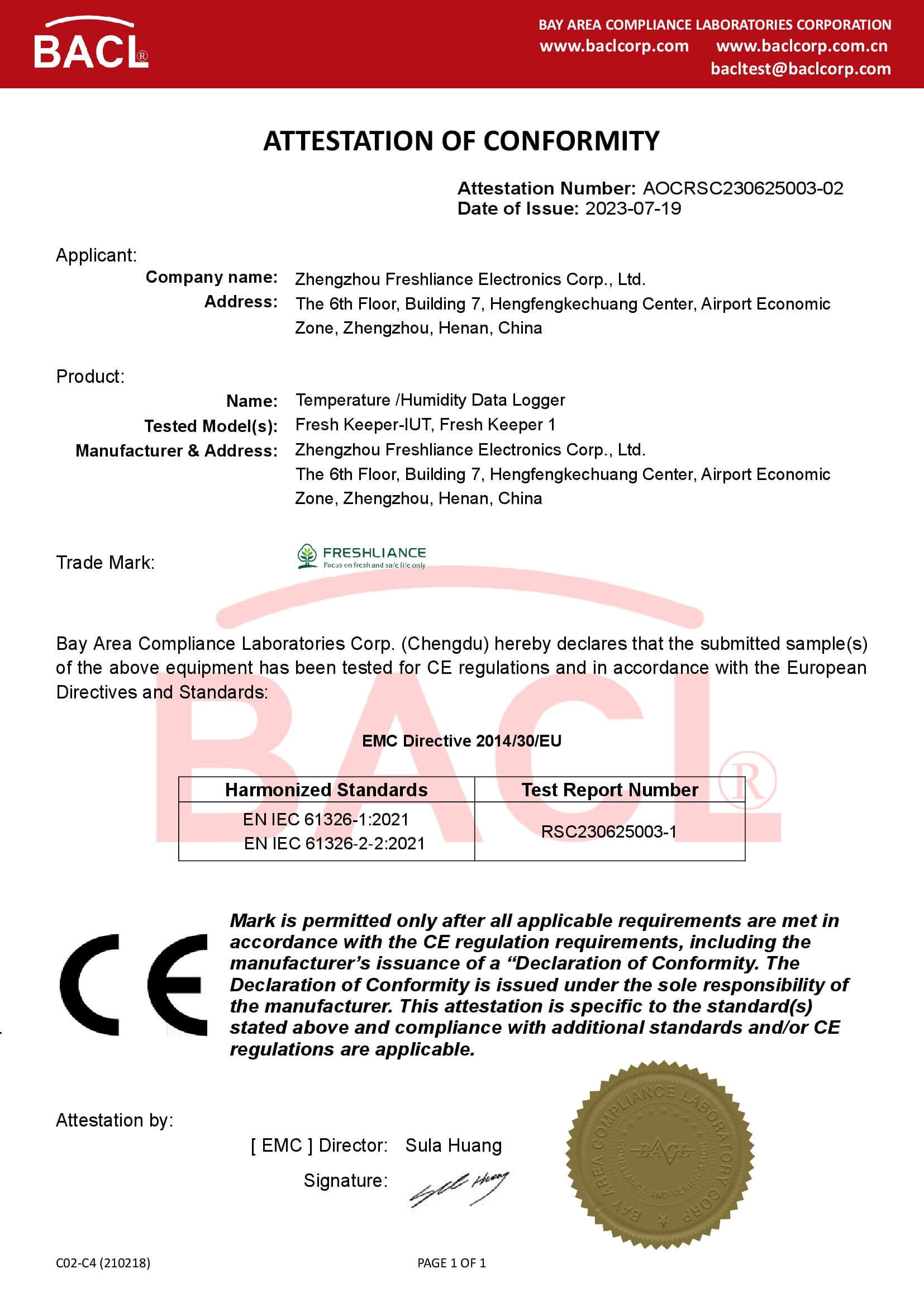

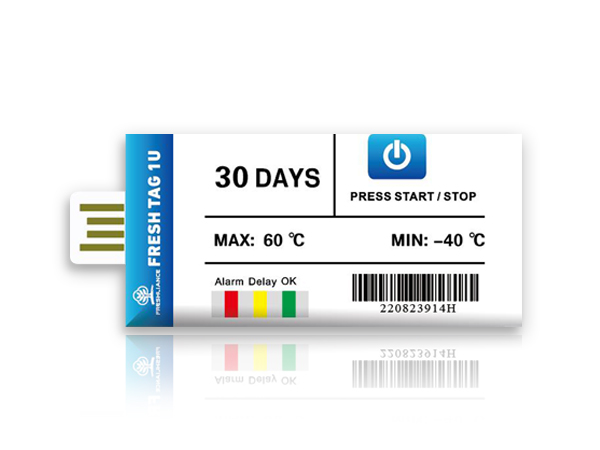

Owing to the high sensitivity of kiwifruit, they must be transported and stored by cold chain and under a certain temperature. Freshliance Fresh Tag 1 single use USB temperature data logger is an ideal and cost-effective choice for recording kiwifruit’s temperature.

Kiwis represent an excellent source of vitamin C. They are also rich in minerals like potassium, iron and calcium. Compared to other fruits, kiwis are naturally lower in sugar and higher in fiber. The demand for kiwi is gaining traction among consumers worldwide, strengthened by consumers’ growing concern for health and wellness. The transport means of kiwifruits mainly are aircraft, ship, truck, railroad. Owing to the high sensitivity of kiwifruit, they must be transported and stored by cold chain and under a certain temperature.

For the good preservation of kiwis, it is essential to use pre-cooling, that is to say, to put them under low temperatures as soon as possible after the harvesting. The optimal temperature for storage is between -1 and +1°C. The freezing point of kiwis is around -2ºC and -2.5ºC. So cold storage temperatures below -1ºC may bring about serious consequences, such as alterations of the pulp, and a slightly unpleasant taste... As the fruit flesh temperature rises, so does the rate of softening, thus to ensure the safe carriage of kiwi fruit and good storage life, the fruit flesh temperature should not be allowed to rise above 1°C. Kiwis must be cooled at 0ºC and preserved in storerooms with relative moisture of around 95%. The use of a controlled atmosphere enables their storage for up to 5 months.

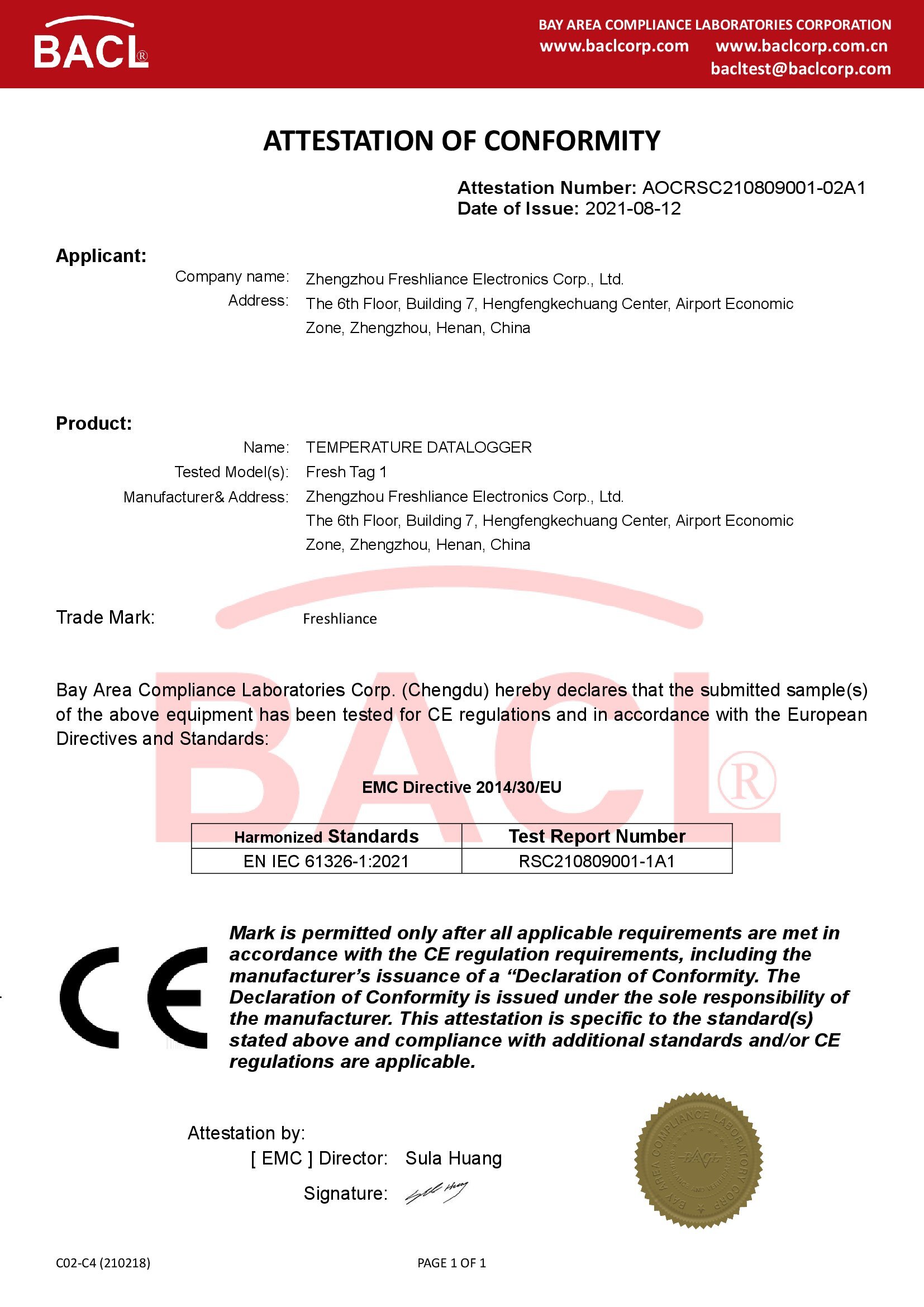

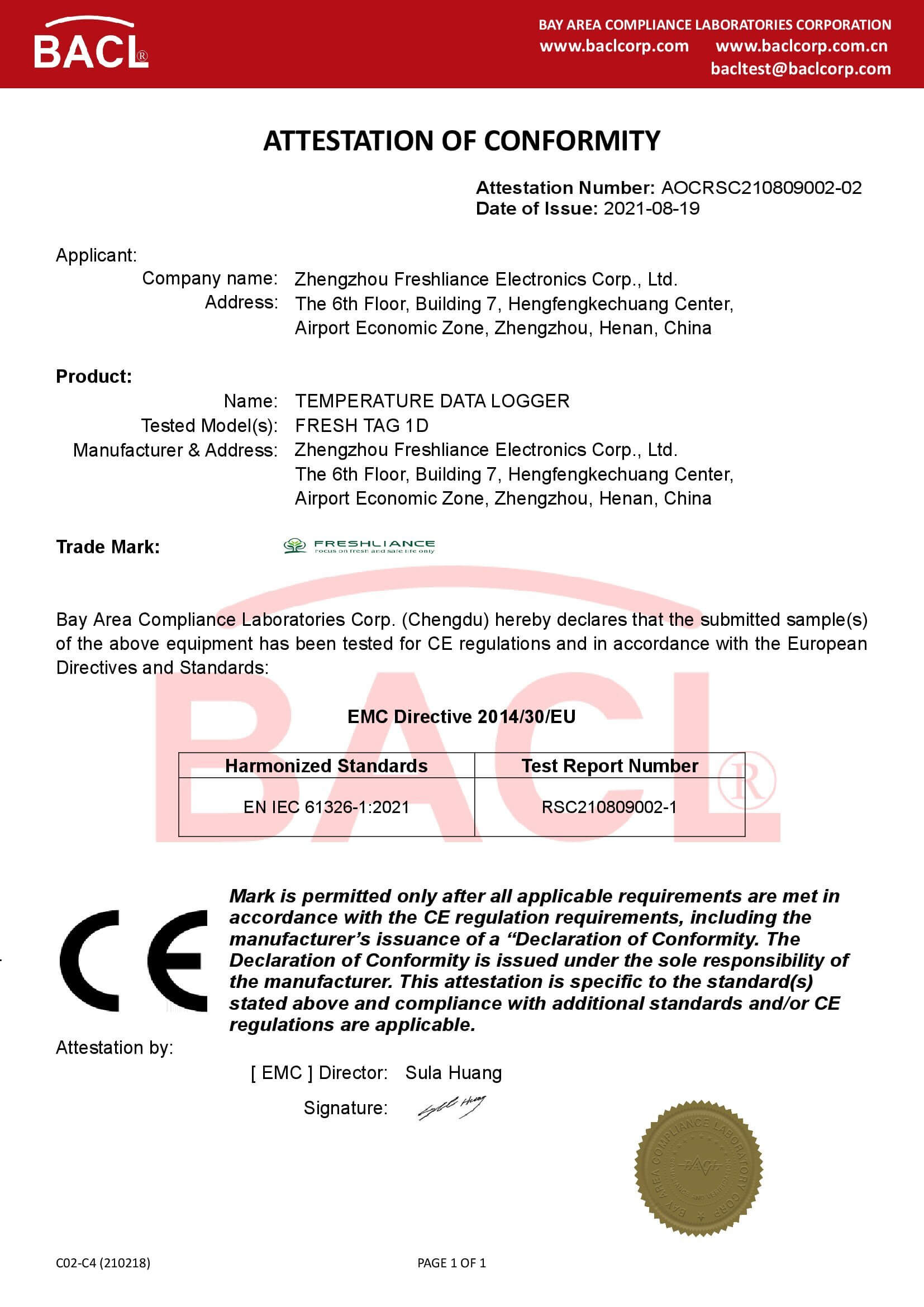

Freshliance single use USB temperature data logger comes with a compact design to save space during transportation. You can place these temperature data loggers with your cargo in ships and trucks. Besides, this USB temperature sensor is equipped with red, green and yellow indicators, which can indicate its alarm, ok and fault status. Our Fresh Tag 1 single use usb temperature data logger has a variety of models to cover 7, 15, 30, 60, 90, 120, or even 180 day trips to meet the concrete needs of various applications. After the trip the completed, you can tear off its plastic bag, and plug it into the computer. The report with graph and table will be automatically generated. This report is the necessary evidence for the product owner and the cold chain carrier if the cold chain performance objection is required.