2 rules to protect bakery products

At the bakery, the fermentation chambers as well as the cold rooms and the freezing cells have become indispensable equipment to control the fermentation and preservation process of pasta and other products.

To meet the demand for bread and pastry products from customers all day long, bakers and pastry artisans need more and more small or large units in positive and negative cold. The first equipments (fermentation or controlled growth chambers) are designed to offer a perfect control of temperatures and humidity. The quality of the blocking process and the control of the shoot will ensure a quality cooking.

Fermentation is the result of three factors: ferment quality, duration and temperature. To improve working conditions, this equipment relies on fermentation temperature and control. Either by slowing down fermentation for one day (growing slowly at a temperature of 10 to 15°) or by blocking fermentation for one to two days (controlled fermentation at a temperature of 4°). Beyond these times of slowdown or blockage, the awakening of the products must be done gently by a very progressive rise in temperature. This delayed fermentation is possible thanks to the controlled fermentation chambers, which regulate both the temperature from 0 to 30° and control the humidity so as to prevent the dough from drying out. The second equipment (freezers and fast cooling cells) will make it possible to freeze and preserve your products by anticipating the evolution of your production over a certain time.

Monitor the cold chain

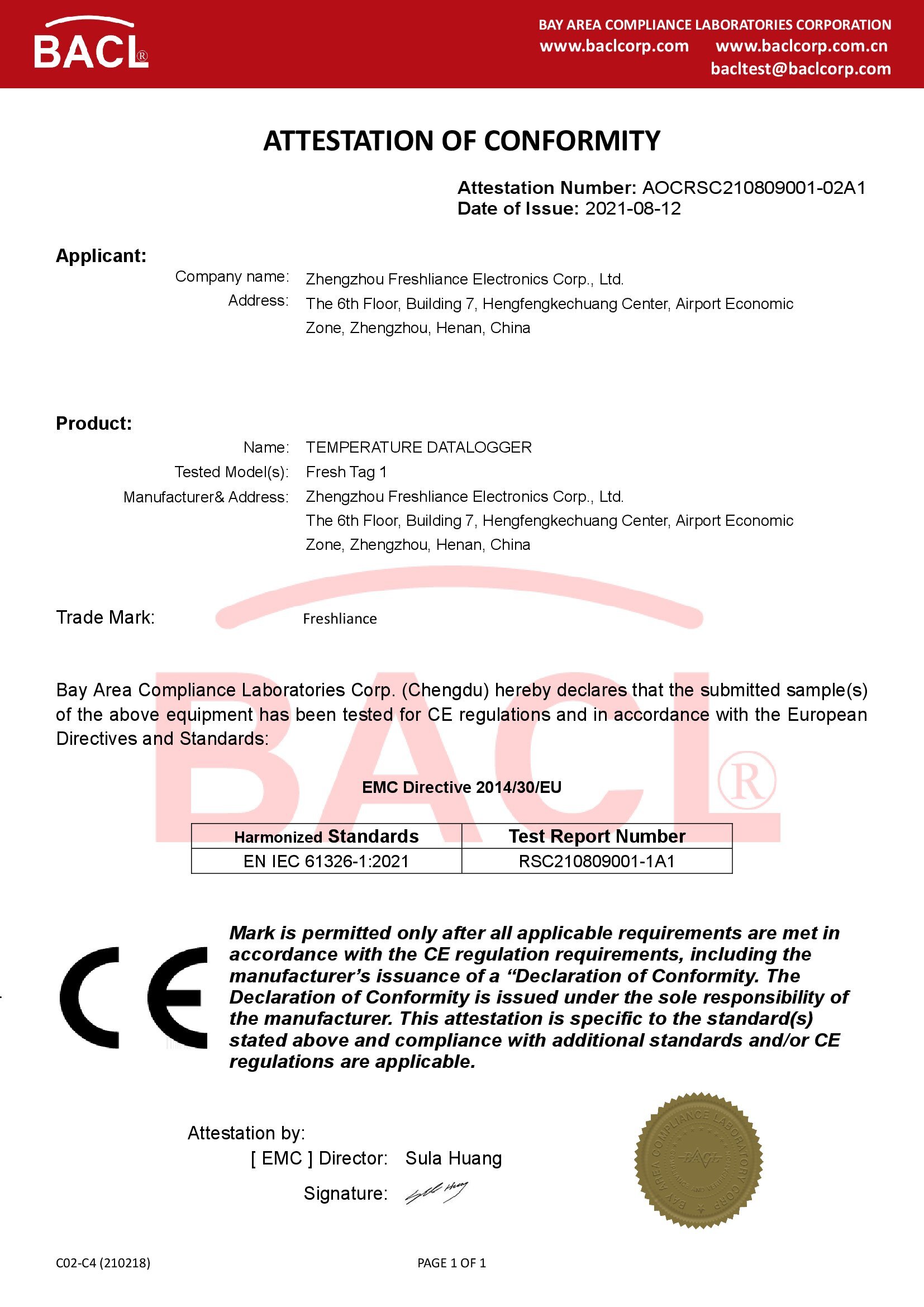

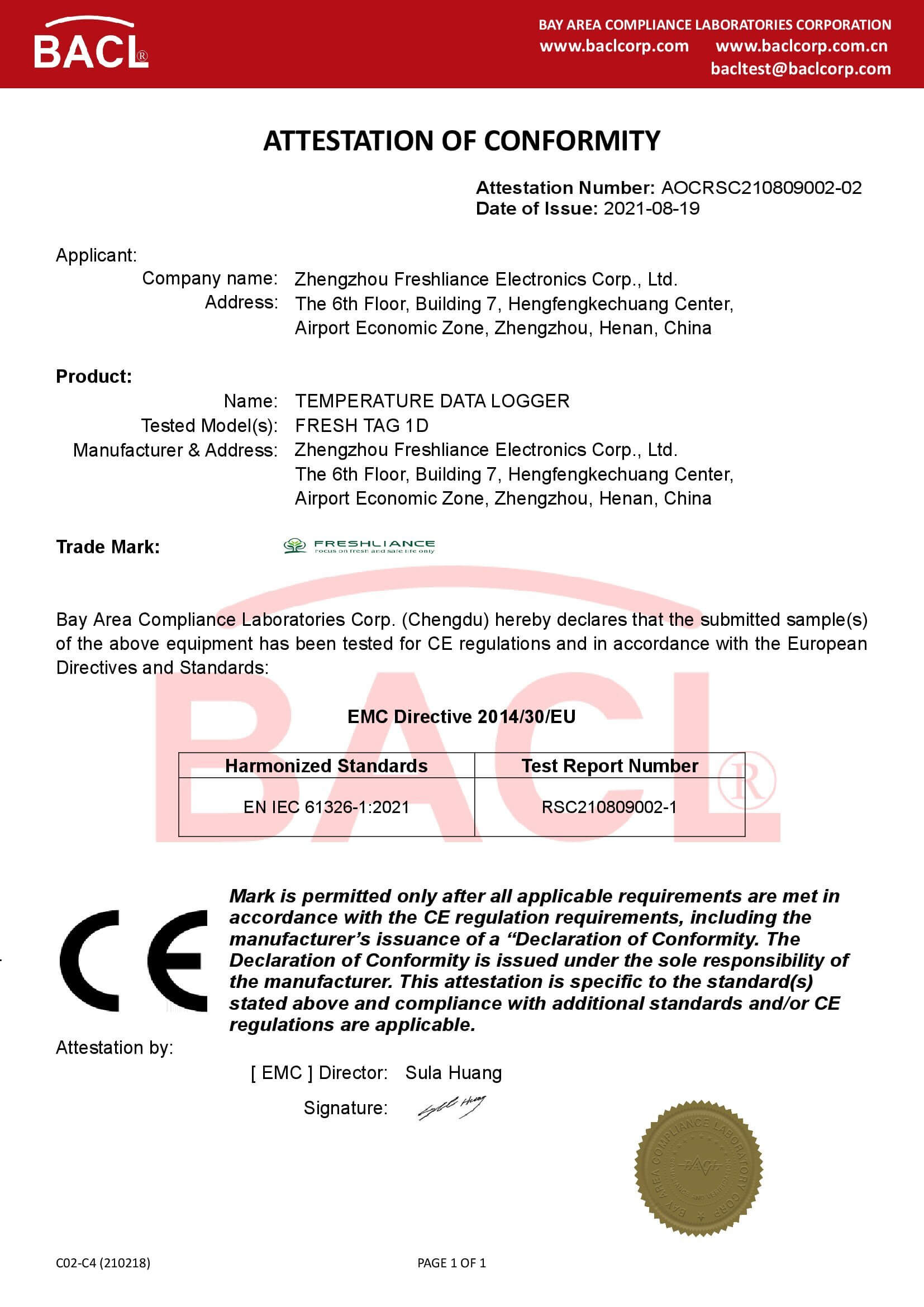

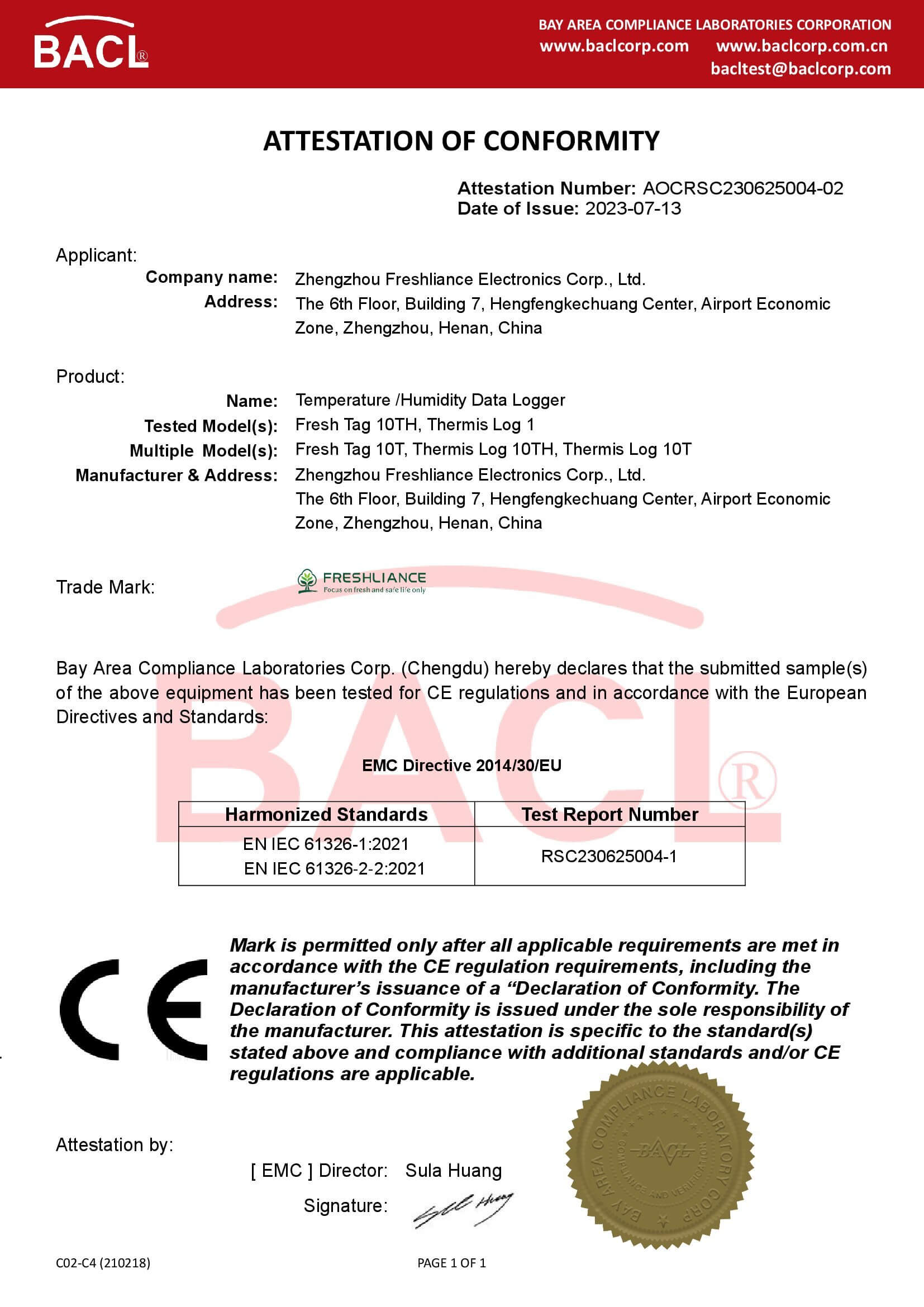

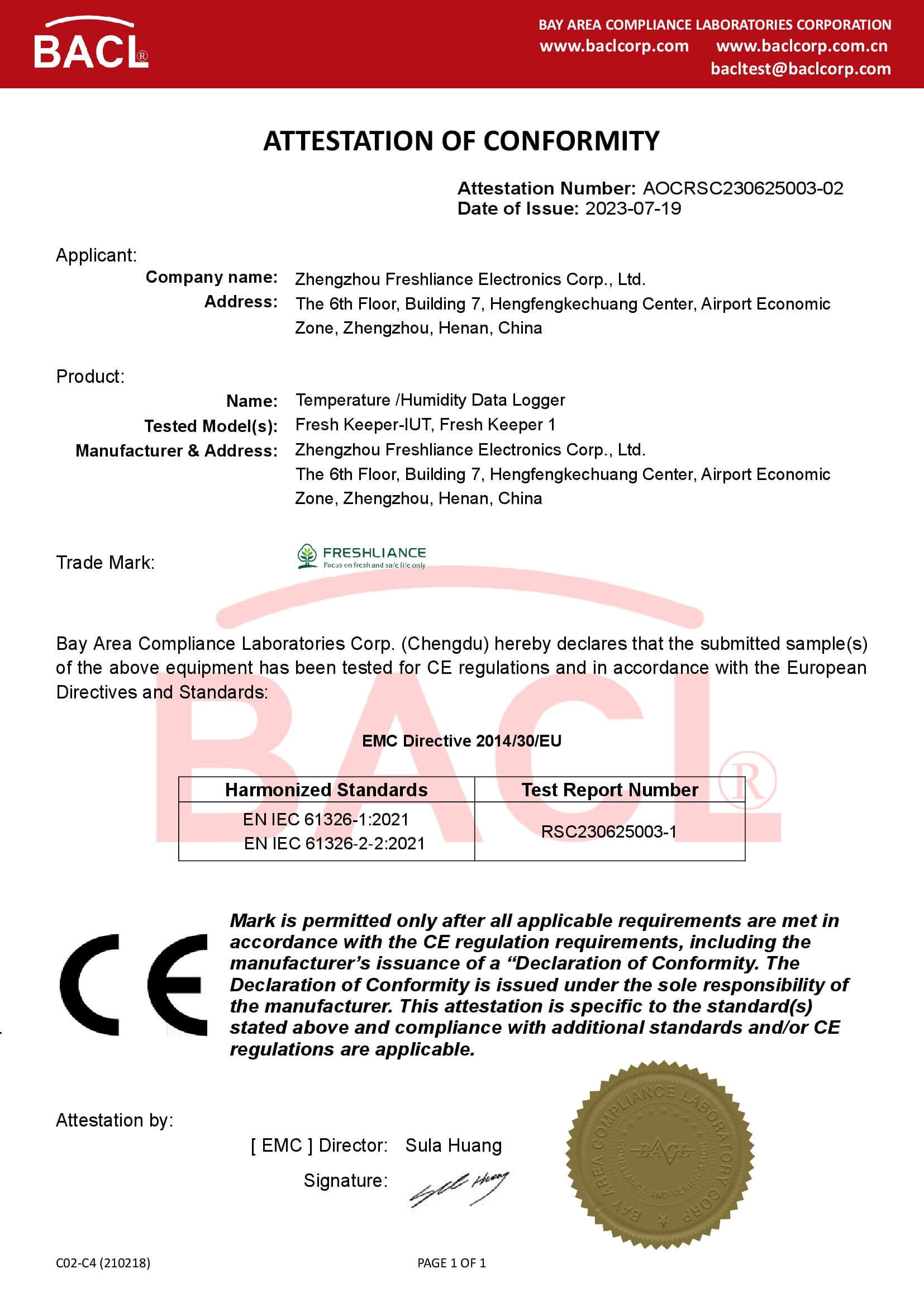

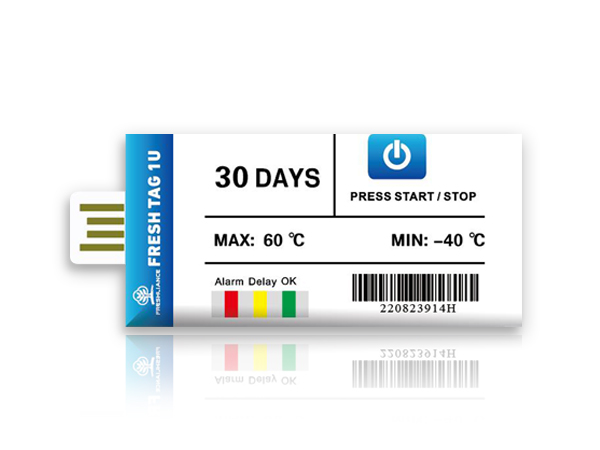

In terms of food hygiene, maintaining the cold chain is the key element in the quality of products. According to the European Food Safety Authority (Efsa), there are several devices to secure temperatures and today connected objects are landing for better control.

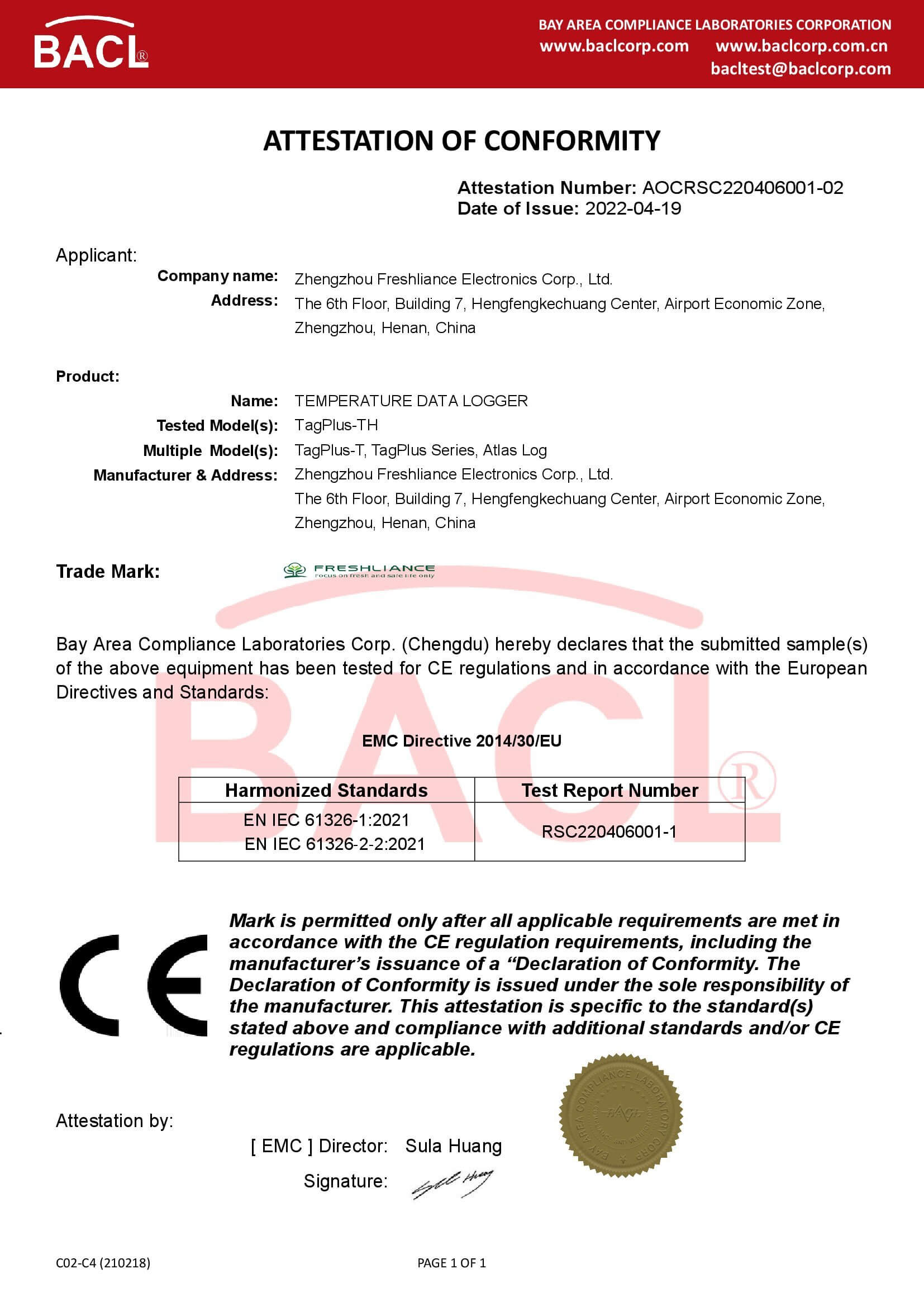

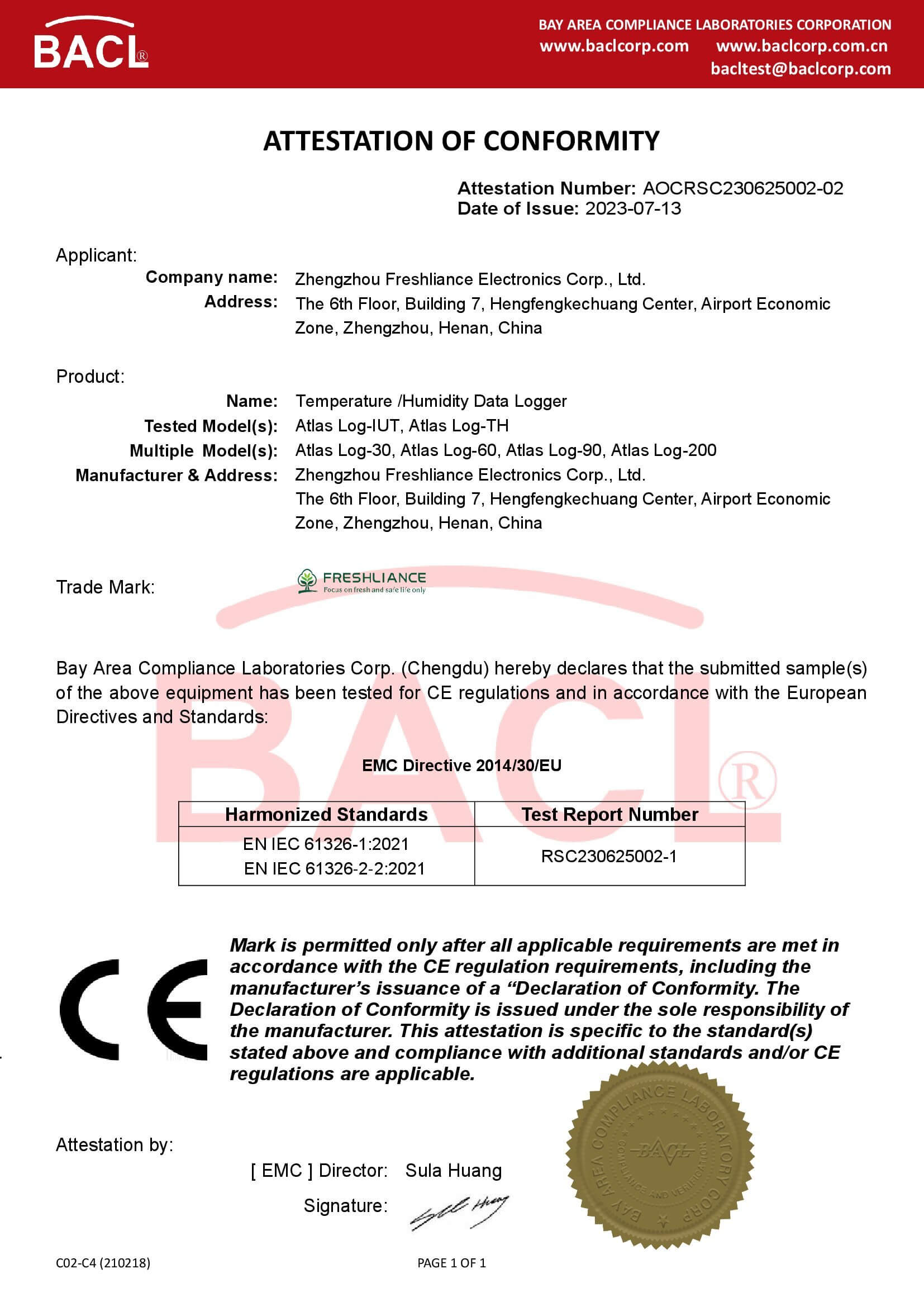

An innovation in the field of cold chain control is the temperature data logger. COEUS-WIFI is a configurable and rechargeable HACCP WIFI temperature and humidity data logger with an LCD display, which can generate PDF and CSV files. The integrated PDF/CSV file generation function allows the HACCP temperature sensor to directly generate non-modifiable data reports in PDF/CSV format.

The wireless COEUS-WIFI HACCP can be programmed with alarm limits of a group of high and low alarms. In case of temperature excursion, the acoustic alarm is activated and the red light flashes to alert. It is ideal to monitor and record the temperature in bakeries.