Cold chain transportation of yogurt Disposable PDF temperature data logger with LCD display

We often see in the supermarket refrigerated air curtain cabinet of low-temperature yogurt, generally using a new low-temperature production process, the packaging is also usually marked storage temperature of 2 ~ 6 ℃. Yogurt will be processed at a high temperature of 55°C to 65°C. After processing, it will be subjected to high-temperature sterilization. At present, most of the dairy factories adopt the pasteurization method, that is to say, they utilize a high temperature of 95℃ for the sterilization process. After sterilization, it should be fermented at high temperature between 40℃~43℃. After fermentation, yogurt needs to be cooled quickly to 5 ℃ to ensure the texture, taste and flavor of yogurt. There is a strict time limit for the cooling rate of yogurt. In addition, the cooling time also has a strict control range. For example, cups of yogurt, depending on the specifications, must be completed within half an hour to one and a half hours from about 20 ℃ to 2 to 4 ℃, so as to stabilize the amount of active substances produced by the active bacteria lactobacillus fermentation in yogurt, and to safeguard the nutrients of yogurt from being destroyed.

Packaged yogurt also needs to be stored in a low-temperature cooler. The cold storage needs to be at a constant temperature of 2℃ to 6℃, generally around 4℃ is appropriate. In the process of cold chain transportation, yogurt also needs to do the whole cold chain, the yogurt will be transported to the cold chain car, to ensure that the product can not be in contact with the ambient air, which requires the refrigerated car and the cold storage door "no difference" docking. Only when the carriage temperature reaches 15 ℃ below the carriage import and export and cold storage door docking, the cold storage of yogurt can be loaded on the refrigerated car transportation. It is not difficult to find that cold chain logistics, cold storage, refrigerated trucks, fresh cabinets and other refrigeration equipment to ensure the quality of low-temperature yogurt. Low-temperature yogurt from the factory to the consumer's mouth, any one of the links to make a mistake will affect its taste and nutrition.

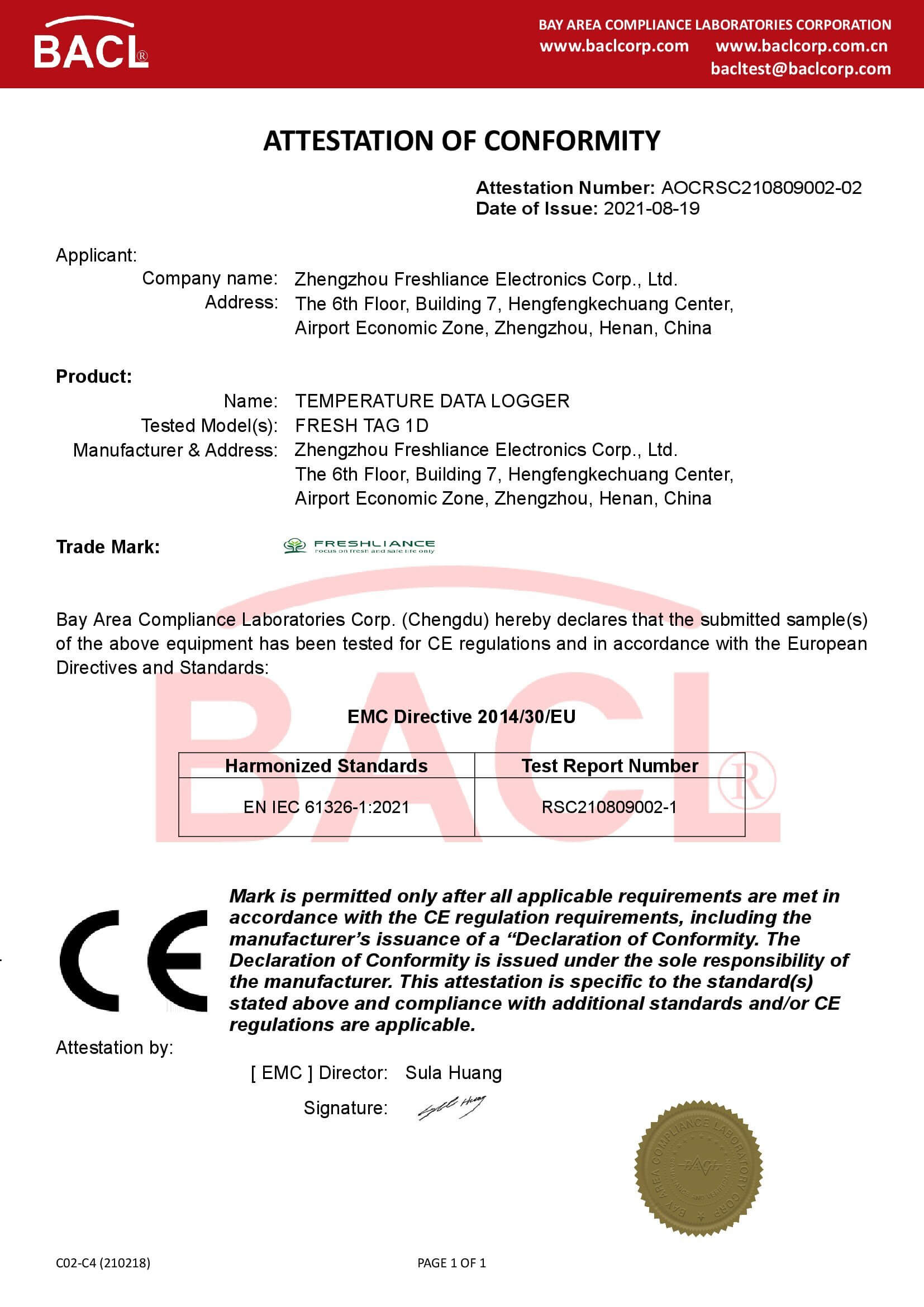

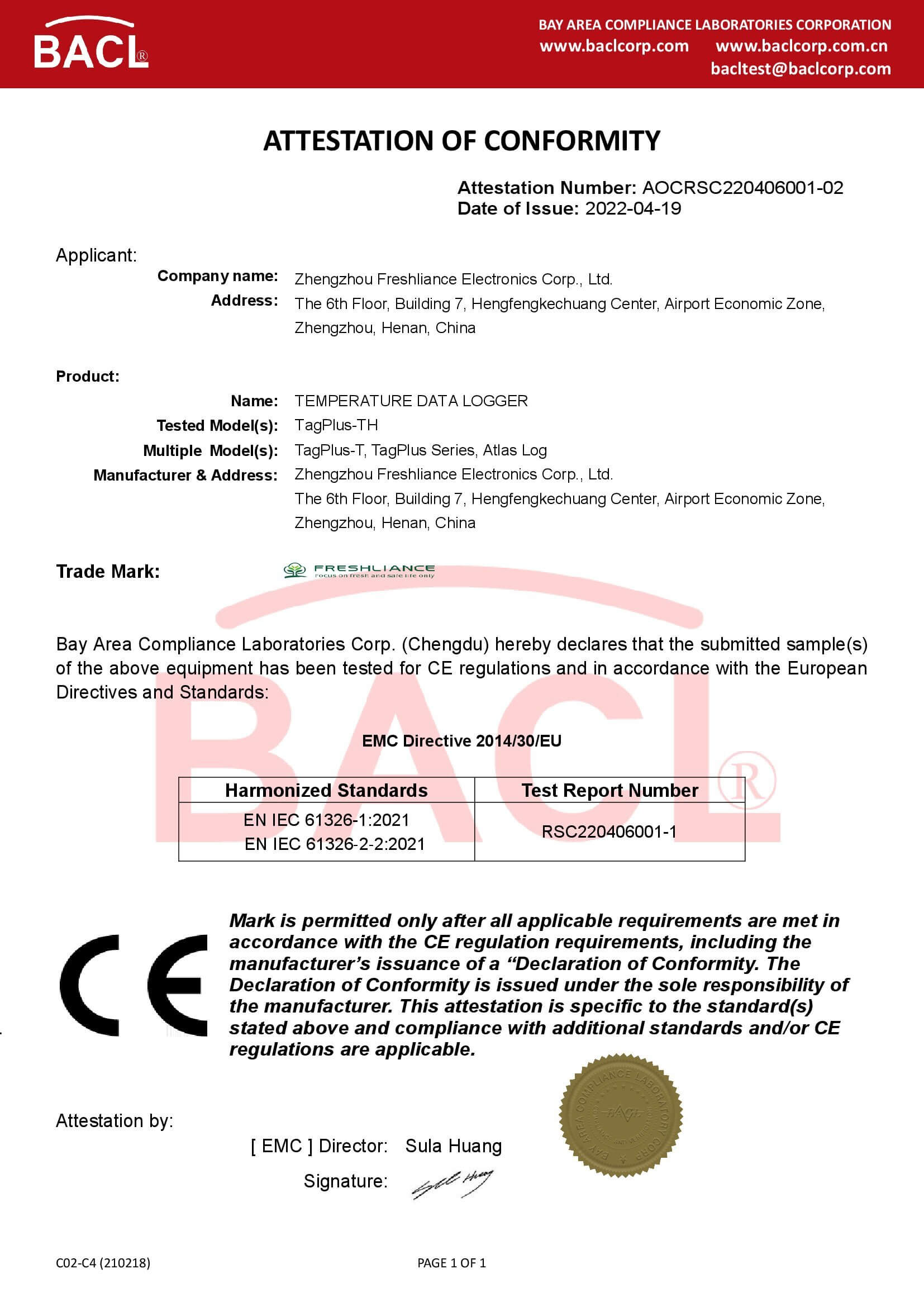

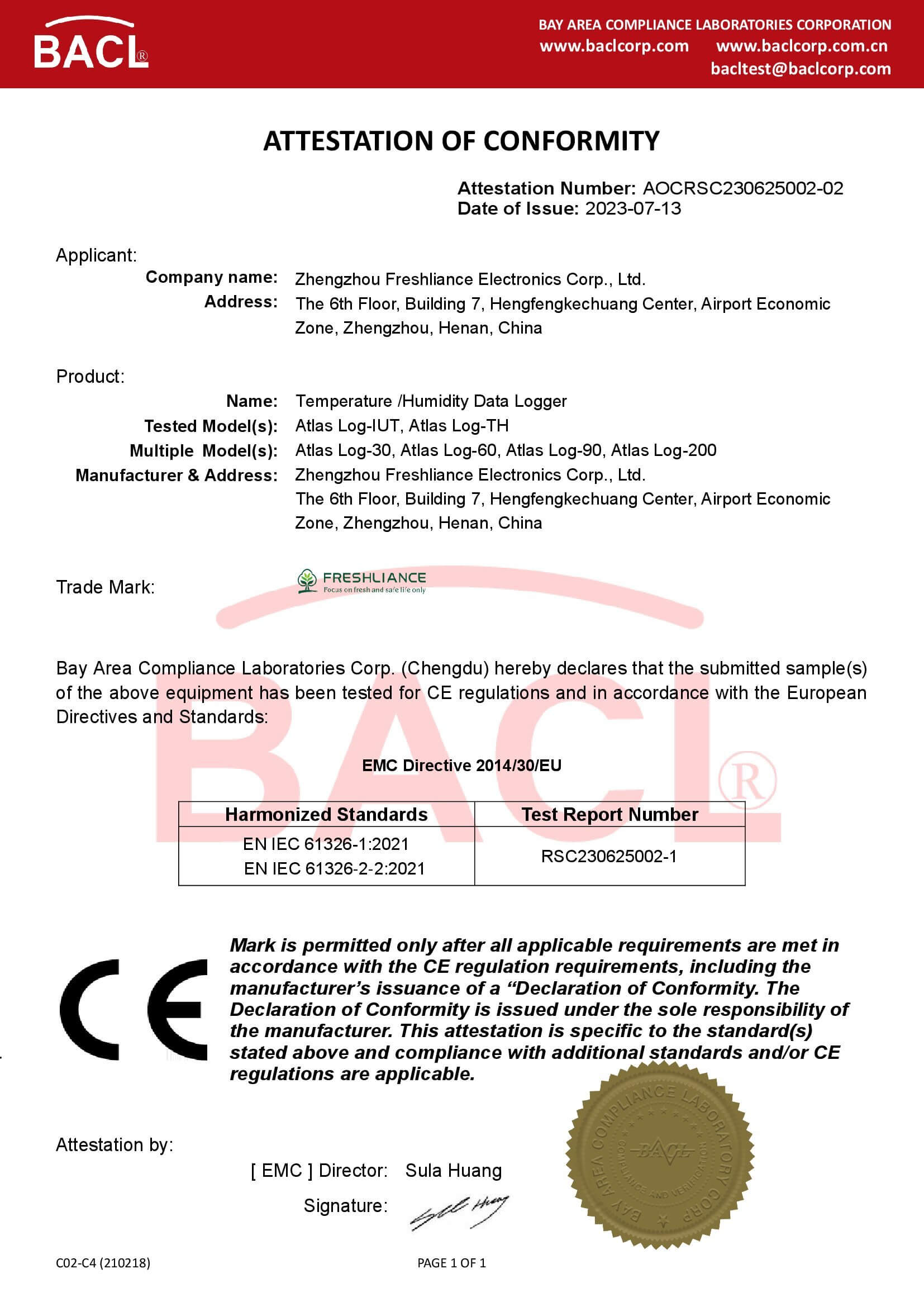

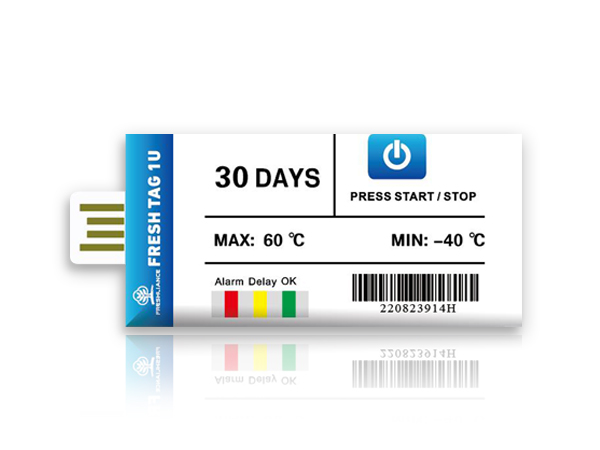

Fresh Tag 1D is a disposable PDF temperature data logger with LCD display function that makes it easy to view real-time temperature data. Its built-in PDF file generation function allows the logger to be plugged into a PC to generate unmodifiable PDF data reports without additional software. This disposable PDF temperature data logger has the advantages of low cost, easy operation and small space occupation. The product is made of food grade packaging materials. It is compact, light, waterproof and widely used. It is an ideal choice for monitoring and recording the temperature changes of sensitive goods during transportation.