How Temperature data logger works in food processing workshop Reusable temperature and humidity data logger

Temperature data loggers are a common device in modern food processing workshops and play an important role in the production process. They can monitor and record temperature changes during food processing, which is crucial in ensuring food quality and safety.

In food processing workshops, temperature data loggers are usually installed at key locations such as ovens, cold rooms, refrigeration equipment, and heating equipment. They can record and measure temperature changes in these devices and alert production managers in time for necessary intervention and adjustment. This is essential in ensuring the safety of food during processing, stability in the laboratory, and consistency in quality. And it can help production managers to identify faulty equipment for timely repair or replacement. Additionally, they can assist managers in developing more precise plans to ensure that food processing is carried out within the appropriate temperature range.

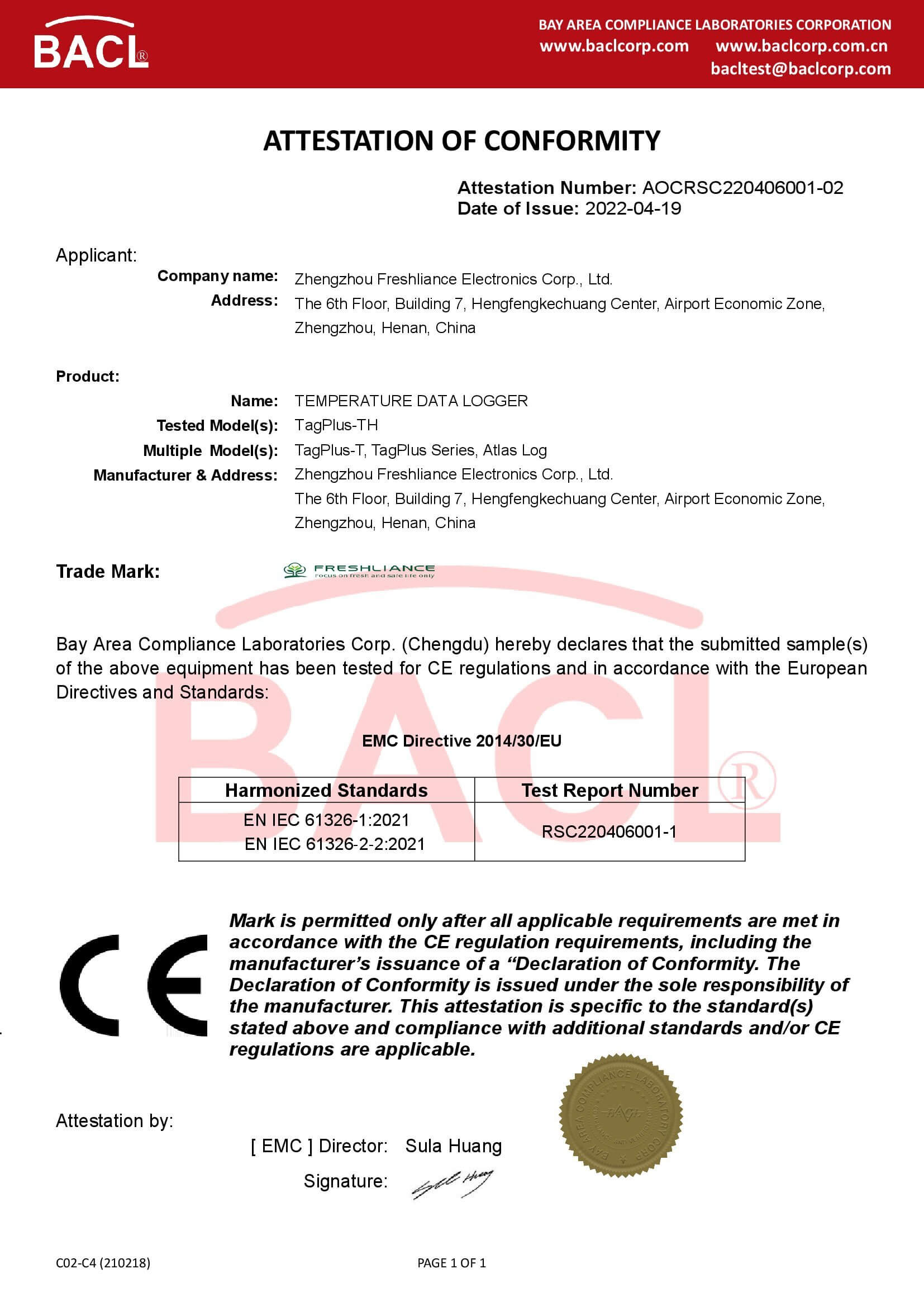

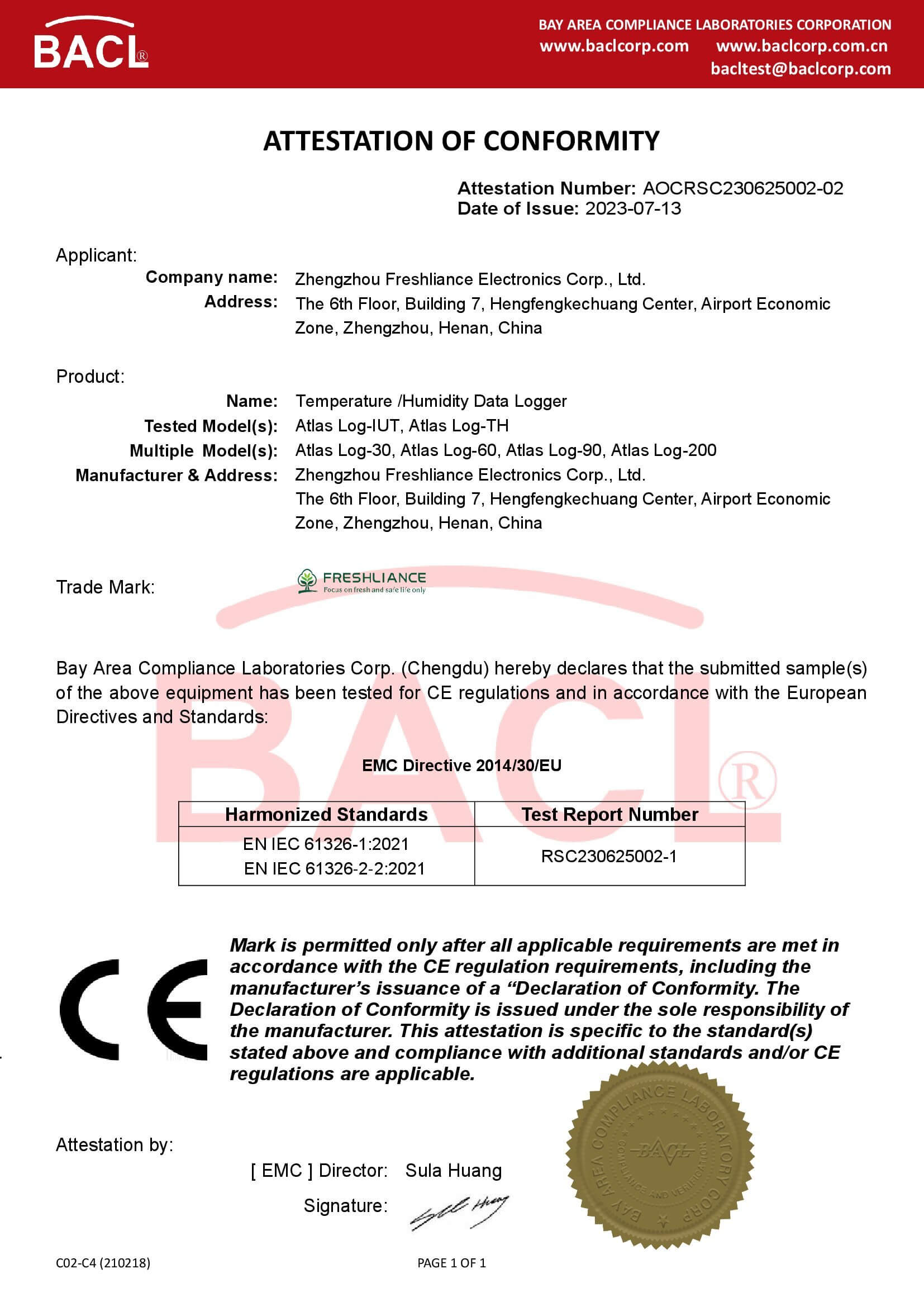

The TagPlus-TH is a reusable temperature and humidity data logger with LCD display for easy visualization of temperature data. In this device, parameters can be set by a professional user prior to use. The complete trip history is recorded and downloaded in the form of numerical reports with summary data, graphs and tables. You can read the report directly on your PC. Temporary mode allows the thermometer to continue operating once users have generated and read the temporary report. It's an ideal choice for monitoring and recording temperature and humidity variations of sensitive products during transport. In conclusion, temperature data loggers are an essential device for modern food processing workshops. They can help production managers to timely identify changes in the production process and take appropriate measures to ensure food quality and safety.