Real-time Temperature and Humidity Monitoring for Steel Foundry

The caption foundry has strict requirements for temperature and humidity, especially in the shell making process. The environmental conditions may directly affect quality of foundry goods. The casting room is generally controlled at the temperature of 20℃~27℃ and the humidity of 40%RH~65%RH, and it is best to maintain a relative constant temperature and humidity. Thereby, temperature and humidity monitoring is particularly important for improving quality of the foundry goods and the quality management system.

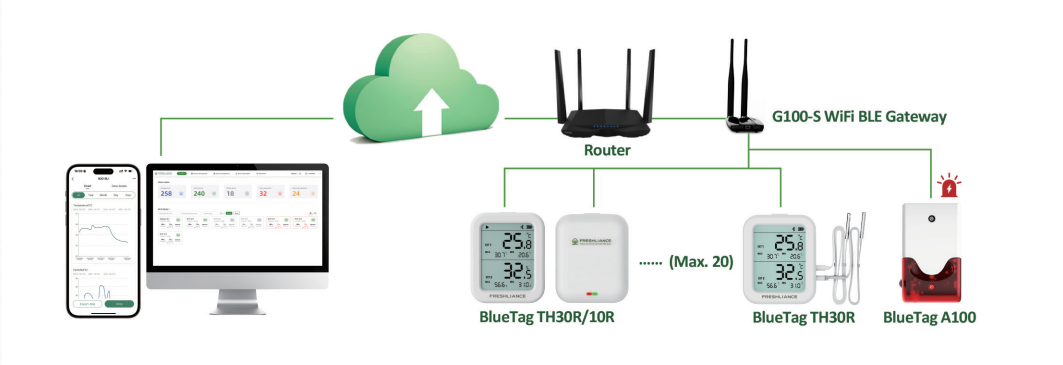

With the popularization of Internet of Things technology, smart real-time environmental monitoring solutions have served us well. For small-scale spaces, Freshliance has developed a real-time temperature and humidity monitoring solution based on WiFi Bluetooth gateway and Bluetooth sensors, BlueTag TH10R and BlueTag TH30R. Up to 20 sensors can be attached to one gateway. This solution enables users to check and track temperature and humidity data in real time via a computer or mobile phone, and immediately get notified via APP push, SMS or email messages if any alarm points are exceeded. All data will also be automatically summarized and analyzed on the computer platform and mobile APP, helping users to effectively improve automated temperature and humidity control of the casting workshop, reduce labor costs and manual errors, and thereby improve casting quality and production efficiency.